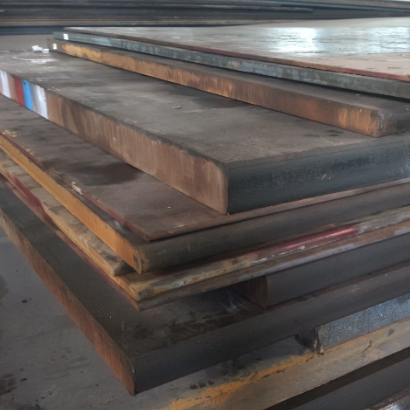

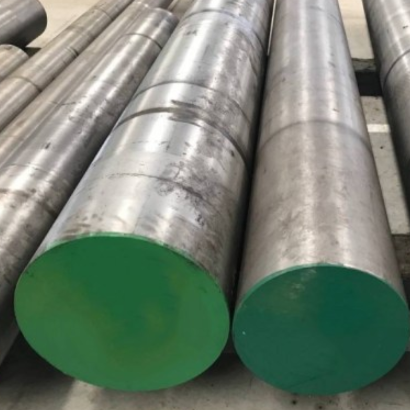

20CrMnSi Alloy steel

20CrMnSi has high strength and toughness, high plasticity in cold deformation and good stamping performance. It is suitable for cold drawing, cold rolling and other cold working processes. It has good weldability, low hardenability and high temper brittleness, so it is not used for carburizing or other heat treatment. If necessary, 20CrMnSi steel can also be used after quenching and tempering. It is generally not suitable for carburizing or other heat treatment except in some cases.

20CrMnSi equivalent grade

| GB | GOST | AISI/ASTM |

| 20CrMnSi | 20KHGSA | – |

20CrMnSi properties

Tensile strength σ B (MPA): ≥ 785 (80)

Yield strength σ s (MPA): ≥ 635 (65)

Elongation δ 5 (%): ≥ 12

Reduction of area ψ (%): ≥ 45

Impact energy Akv (J): ≥ 55

Impact toughness value α kV (J / cm2): ≥ 69 (7)

Brinell hardness (hbs100 / 3000) (annealed or tempered at high temperature): ≤ 207