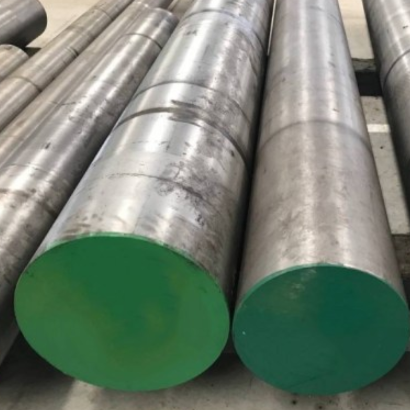

25Cr2MoV steel has good intergranular corrosion resistance, excellent corrosion resistance and cold working stamping performance. It has strong corrosion resistance to oxidizing acid (such as nitric acid), alkali solution and most organic and inorganic acids.

Due to its proper hardenability, the microstructure of the alloy is homogeneous sorbite, bainite or very fine pearlite after proper metal heat treatment. Therefore, 25Cr2MoV has higher tensile strength and yield ratio, higher toughness and fatigue strength, and lower toughness and brittle transition temperature.

Generally, the steel material can be used in the state of quenching and tempering, and can also be used after normalizing and high temperature tempering.

25Cr2MoV steel mechanical properties:

Tensile strength σ B (MPA): 1090

Yield strength σ s (MPA): 1042

Elongation δ 5 (%): 18

Reduction of area ψ (%): 63

Impact toughness value α Ku (J / cm2): 213

Hardness: 308HB