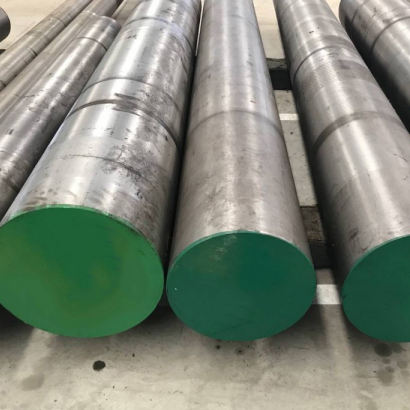

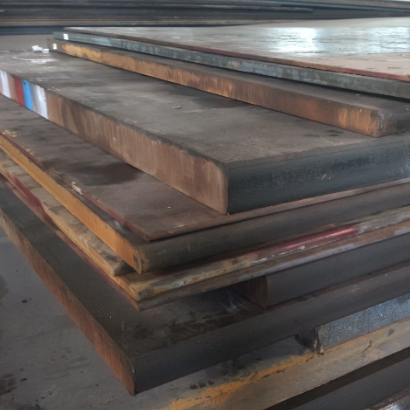

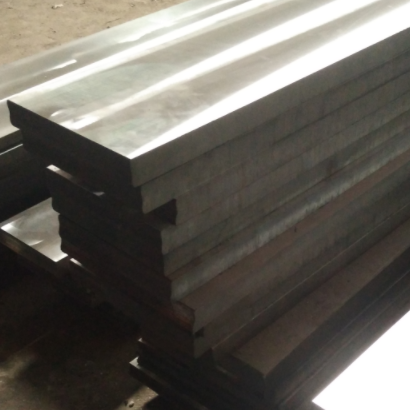

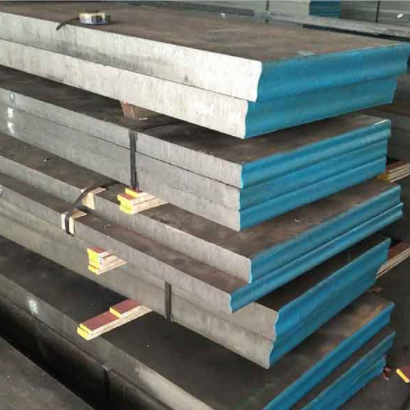

Thousand tons 30CrNiMo8 stocking

30CrNiMo8 steel is German DIN standard in Q+T (quenched and tempered steel), equivalent to 30cr2ni2mo in China.

30crnimo8 material has high yield strength, tensile strength and fatigue strength, and sufficient plasticity and toughness.

Generally, EAF and BOF are used for smelting, and secondary refining, electroslag remelting or vacuum treatment, vacuum induction furnace smelting or double vacuum smelting and appropriate heat treatment are adopted for those with high requirements.

The material 30CrNiMo8 is difficult to machine. 30CrNiMo8 to achieve hrb80 below is very difficult, generally do about hrb85 can.

30crnimo8 equivalent grade

| EN | 30CrNiMo8 – 1.6580 | ||||||||

| 0.26 – 0.34 | 0.3 – 0.6 | <0.4 | <0.025 | <0.035 | 1.8 – 2.2 | 1.8 – 2.2 | 0.3 – 0.5 | – | |

| PN | 30H2N2M | ||||||||

| 0.26 – 0.34 | 0.3 – 0.6 | 0.17 – 0.37 | <0.035 | <0.035 | 1.8 – 2.1 | 1.8 – 2.1 | 0.25 – 0.35 | <0.2 | |

| NF | 30CND8 / 30NCD8 | ||||||||

| 0.26 – 0.33 | 0.3 – 0.6 | 0.1 – 0.4 | <0.030 | <0.025 | 1.8 – 2.2 | 1.8 – 2.2 | 0.3 – 0.5 | – | |

30crnimo8 steel properties

30CrNiMo8 steel belongs to DIN alloy structure tempered steel, which has high yield strength, tensile strength, and enough plasticity and toughness. The critical temperature of Ac3 in 30crnimo8 heat treatment is 800℃, and the quenching temperature is Ac3+(30 ~ 70)℃. After comprehensive consideration, the process was determined as follows: normalizing 880℃, holding heat for 5h; The quenching temperature is 840 ~ 860℃, and the holding time is 4 ~ 4.5h. Water quenching oil is used for quenching and tempering temperature is 570 ~ 620℃. The tempering time should not only ensure that the tissue transformation can be fully carried out through through burning, but also try to eliminate the residual stress.