30CrNiMo8 Steel in Action

For steel wholesalers and distributors, understanding the nuances of different alloys is crucial to meeting the diverse needs of clients across various industries. In this article, we’ll explore the intricacies of 30CrNiMo8 steel, providing valuable insights and practical tips to help you navigate the complexities of working with this high-performance alloy.

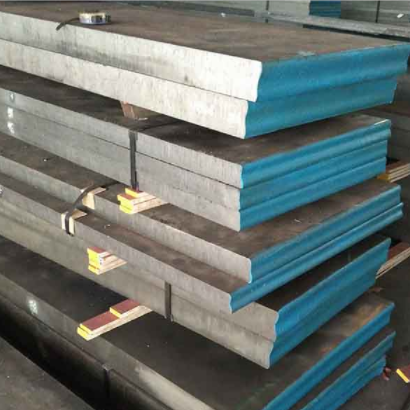

Getting to Know 30CrNiMo8 Steel:

30CrNiMo8 steel is a chromium-nickel-molybdenum alloy known for its exceptional strength, toughness, and hardenability. Its composition lends itself to a wide range of applications where high tensile strength and excellent fatigue resistance are required. To fully harness the potential of 30CrNiMo8 steel, it’s essential to understand its properties and how they influence its performance in different scenarios.

Optimizing Machining and Fabrication:

When machining 30CrNiMo8 steel, it’s important to use appropriate cutting tools and techniques to achieve the desired results. Due to its high hardenability, the alloy can be challenging to machine in its hardened state. Therefore, pre-machining annealing may be necessary to facilitate machining operations.

During heat treatment, precise control of temperatures and cooling rates is critical to achieving the desired microstructure and mechanical properties. Proper quenching and tempering processes can enhance the steel’s strength, toughness, and wear resistance, making it suitable for demanding applications.

Best Practices for Handling and Storage:

Proper handling and storage of 30CrNiMo8 steel are essential to maintain its integrity and performance. Avoid rough handling and exposure to moisture, which can lead to surface corrosion and degradation of mechanical properties. Store the steel in a clean, dry environment, preferably indoors, to prevent contamination and ensure optimal condition.

Why Choose OTAI’s 30CrNiMo8 Steel:

As a leading steel stockist, OTAI offers a comprehensive range of 30CrNiMo8 steel products tailored to meet the diverse needs of customers. With OTAI, you benefit from a reliable supply chain, ensuring that the steel you need is always available when you need it. Furthermore, OTAI’s commitment to quality and customer satisfaction is evident in its extensive track record of supplying top-tier companies worldwide.

Real Customer Cases:

Let’s examine two real customer cases that illustrate the value of partnering with OTAI for your 30CrNiMo8 steel needs:

- Heavy Machinery Manufacturer: A leading manufacturer of heavy machinery required high-quality 30CrNiMo8 steel for the production of critical components. OTAI provided timely delivery of the steel, meeting the customer’s specifications and enabling seamless integration into their manufacturing process.

- Oil and Gas Supplier: An oil and gas supplier needed reliable steel for drilling equipment operating in harsh environments. OTAI supplied 30CrNiMo8 steel with exceptional durability and resistance to wear and corrosion, ensuring optimal performance and longevity in demanding conditions.

30CrNiMo8 Steel in Action, mastering the art of working with 30CrNiMo8 steel requires a combination of technical expertise, precision machining, and attention to detail. With OTAI as your trusted partner, you gain access to high-quality steel backed by unrivaled support, ensuring that your projects meet the highest standards of performance and reliability. Invest in OTAI’s 30CrNiMo8 steel today and elevate your business to new heights of success.