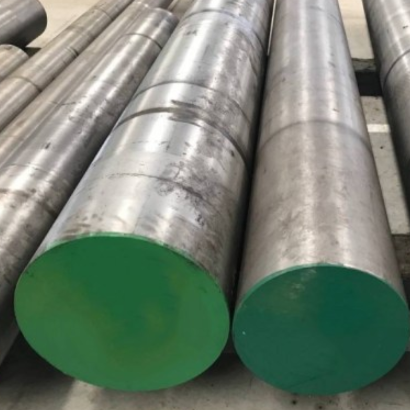

40Cr engineering steel

40Cr steel is one of the most widely used steels in mechanical manufacturing industry. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. Except from quenching and tempering, the steel is also suitable for cyaniding and high frequency quenching. When the hardness is 174-229hb, the relative machinability is 60%.

The steel is easy to be processed and certain toughness, plasticity and wear resistance can be obtained after proper heat treatment. Normalizing can promote the microstructure refinement, close to the equilibrium state, and improve the cutting performance of the blank. The steel has the best comprehensive mechanical properties when tempered at 550 ~ 570 ℃. The hardenability of the steel is higher than that of 45 steel, which is suitable for high frequency quenching, flame quenching and other surface hardening treatment.

40Cr equivalent grade:

| GB | AISI/SAE/ASTM | JIS | ISO | DIN | UNI |

| 40Cr | 5140 | SCr440(H)/SCr440 | 41Cr4 | 1.7035/1.7045 | 41Cr4 |

40Cr Mechanical Properties:

Tempering heating temperature (℃): 520;

Tensile strength (σ B / MPA): ≥ 810 (when the actual hardness is 25hrc)

Yield point (σ s / MPA): ≥ 785

Elongation after fracture (δ 5 /%): ≥ 9

Reduction of area (ψ /%): ≥ 45

Shock absorption energy (aku2 / J): ≥ 47

Brinell hardness (100 / 3000hbw) (annealed or tempered at high temperature): ≤ 207