You Need to Know About 4140 Plate Steel Specifications

You Need to Know About 4140 Plate Steel Specifications

Introduction

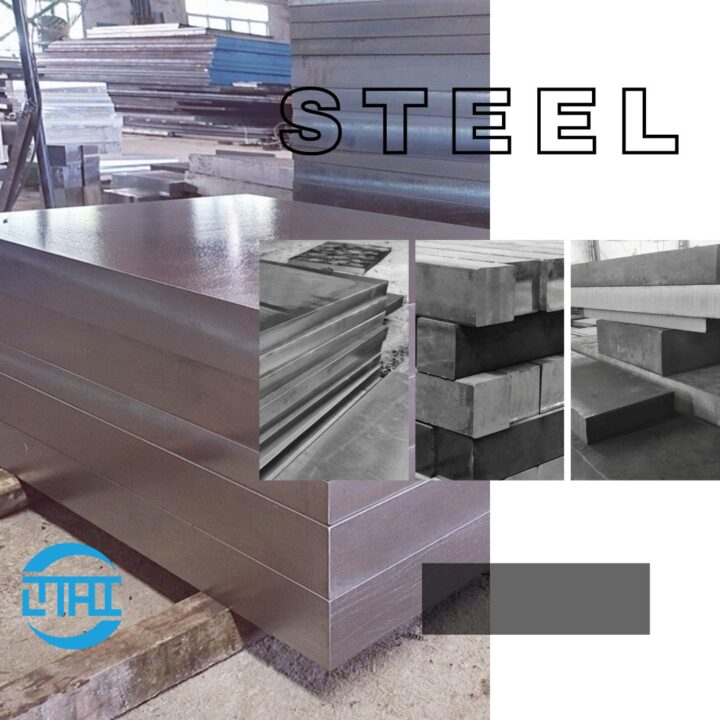

Imagine a material possessing the strength of a tank yet versatile enough for applications ranging from automotive components to towering skyscrapers. Meet 4140 plate steel. If you’re looking for a material that can handle the demands of your project, you’ve come to the right place. Dive into this comprehensive guide to 4140 steel, exploring its exceptional properties and specific applications.

4140 Steel Properties and Attributes

Outstanding chemical composition: 4140 steel resembles a superhero among metals, drawing its strength from a distinctive combination of elements like chromium and molybdenum. These components provide the durability and resilience necessary to confront any challenge.

Mechanical properties: Strength – Following heat treatment, 4140 steel attains a hardness of 200 to 300 on the Brinell scale, comparable to a robust shield that withstands extensive wear and tear. It excels under high pressure, resistant to fractures, making it perfect for heavy-duty applications.

Physical properties: While not stainless steel, 4140 alloy steel boasts considerable corrosion resistance. Moreover, its ease of weldability makes it a preferred choice across diverse projects. It serves as the Swiss Army knife of metals – always prepared for any task.

Applications of 4140 Plate Steel

Oil and Gas Sector: In the rigorous environment of oil and gas operations, 4140 material stands as a stalwart, utilized in components subjected to high pressure and occasional corrosion. It functions as the reliable guardian of equipment, safeguarding it against harsh conditions.

Automotive Industry: Vehicles demand durable components, where 4140 steel shines. It’s ideal for fabricating gears and other parts requiring robust performance, akin to the vehicle’s core ensuring seamless operation.

Aerospace Applications: For aircraft and spacecraft, where resilience is non-negotiable, 4140 alloy steel rises to the occasion. It excels in parts exposed to significant stress and temperature fluctuations, much like a steadfast astronaut in the realm of metals, prepared for the challenges of space exploration.

Manufacturing and Quality Control of 4140 alloy Steel

Production Process: Commencing with meticulous melting in specialized furnaces, followed by precise rolling to achieve desired dimensions, akin to baking a cake with precise ingredients and baking times.

Quality Assurance: Each batch undergoes rigorous testing to ensure adherence to international standards, ensuring peak performance for your projects. This quality check mirrors a comprehensive health assessment, certifying the steel’s readiness for deployment.

Guaranteed Performance: Our 4140 steel is accompanied by certification, affirming its compliance with the highest industry standards. It stands as a testament to its superior quality, akin to earning a prestigious accolade for excellence.

Customization and Quality Assurance

Tailored Precision: Our precision cutting services ensure that every piece of steel is delivered in exact dimensions, minimizing waste and guaranteeing a precise fit for your specific needs. It’s like commissioning a bespoke suit tailored to perfection, ensuring optimal performance.

Expert Surface Finishing: Following cutting, our steel undergoes meticulous polishing to achieve a brilliant shine or expert grinding to meet precise specifications. This enhances both the aesthetics and functionality of the steel, providing a rejuvenated appearance similar to a refreshing makeover.

Stringent Quality Control: Before shipping, each product undergoes rigorous inspections to ensure flawless quality. This commitment to uncompromising standards is akin to administering a final examination, ensuring the steel is fully prepared for real-world applications and challenges.

Efficient Distribution

Stable Stock: With a warehouse housing over 10,000 tons of 4140 steel plates, we ensure swift delivery regardless of your order size. It’s akin to having a pantry stocked with your favorite foods – reliably available when needed with the 4140 Plate Steel Specifications of 10-300mm.

Logistics Management: Leveraging advanced systems, we track inventory and plan deliveries meticulously, ensuring timely fulfillment of your needs. It’s akin to having a dedicated assistant managing your steel requirements.

Prompt Delivery: Partnering with top-tier shipping providers enables us to deliver your steel promptly, regardless of your location. It’s akin to a speedy delivery service, tailored specifically for steel.

Advantages of 4140 Steel Over Alternatives

Superior Strength and Durability: Compared to other steels, 4140 steel excels in strength and longevity, making it the preferred choice for demanding applications. It’s akin to selecting the star player for your team – dependable and robust.

Value Proposition: Despite its premium quality, 4140 steel offers exceptional value, delivering longevity and superior performance, akin to investing in a car that not only looks stylish but also operates smoothly for years.

Tailored Selection: Choosing the right steel hinges on project specifics. Our experts provide tailored guidance to determine if 4140 steel suits your needs. It’s akin to having a personal shopper for your steel requirements.

You Need to Know About 4140 Plate Steel Specifications

4140 plate steel stands as an exemplary choice for projects necessitating strength and reliability. Understanding its specifications ensures optimal utilization for your endeavors. At OTAI, we take pride in offering top-tier 4140 steel, backed by unparalleled service. Reach out to us to learn more or discuss your requirements – we’re here to assist you every step of the way.