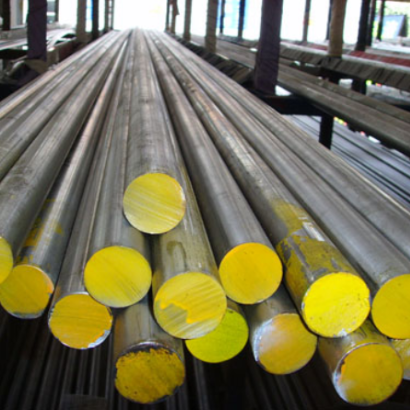

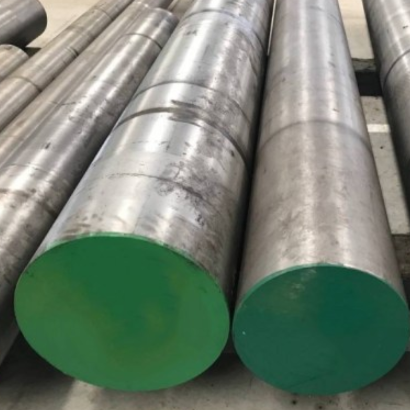

A2 steel is classified as an air-hardening tool steel and primarily comprises iron, carbon, chromium, molybdenum, and vanadium. This combination results in a material that boasts remarkable wear resistance, high toughness, and excellent dimensional stability.

The Allure of Versatility in A2 Steel

Versatility is a trait highly sought after in materials, and A2 steel delivers on this front. Its ability to perform well in various environments, coupled with its ease of machinability, makes it a favorite among engineers and manufacturers alike.

A2 Steel’s Impressive Mechanical Properties

A2 steel’s mechanical prowess is one of its defining features. It exhibits a balanced combination of hardness, toughness, and resistance to deformation, making it a prime candidate for applications where reliability is paramount.

Heat Treatment and Its Influence on A2 Steel

Heat treatment is the secret behind unlocking A2 steel’s full potential. Through processes like austenitizing, quenching, and tempering, engineers can tailor its properties to suit specific applications, enhancing its overall performance.

Applications Across Industries

A2 steel’s versatility shines as it finds applications in a multitude of industries. From aerospace to manufacturing, its adaptability has made it a staple in creating components that demand both precision and durability.

A2 Steel in Toolmaking and Woodworking

The toolmaking industry benefits immensely from A2 steel’s properties. Chisels, hammers, and punches made from A2 steel offer excellent wear resistance and edge retention, enhancing the efficiency of woodworking and metalworking processes.

Automotive and Manufacturing Applications

In the automotive and manufacturing sectors, A2 steel finds its place in forming dies, blanking tools, and intricate components. Its high impact resistance and machinability contribute to the seamless production of complex parts.

A2 Steel in Blades and Cutlery

The culinary world also embraces A2 steel for crafting blades that strike the perfect balance between sharpness and durability. Knives made from A2 steel retain their edge for prolonged periods, enhancing the cooking experience.

A2 Steel vs. Other Tool Steels

When compared to other tool steels, A2 steel stands out due to its combination of wear resistance and toughness. While not as wear-resistant as some counterparts, its overall package of properties makes it a versatile choice.

Challenges in Working with A2 Steel

While A2 steel offers numerous advantages, it’s not without challenges. Its air-hardening nature demands careful consideration during heat treatment to achieve desired results. Proper procedures are essential to avoid cracking and distortion.

The Future of A2 Steel

As engineering techniques and materials science advance, the potential of A2 steel continues to grow. Innovations in manufacturing, heat treatment, and alloying can further expand its applications and fine-tune its properties.

A2 steel’s journey from the crucible to diverse industries is a testament to its exceptional attributes. Its versatility, coupled with impressive mechanical properties, positions it as a valuable asset in modern engineering, where the pursuit of optimal materials never ceases.