Precision engineering is an engineering discipline that focuses on designing and producing components and systems with exceptional accuracy and reliability. It has transformed industries ranging from aerospace to electronics by enabling the creation of intricate and complex structures with minimal tolerances.

The Role of A2 Steel in Precision Engineering

A Metallurgical Marvel

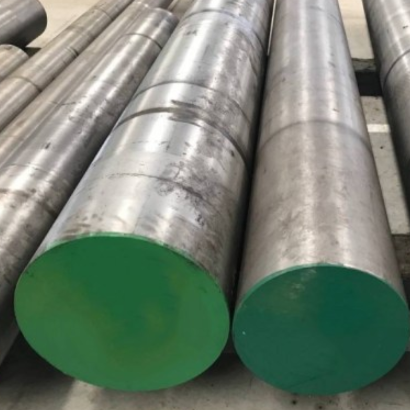

A2 steel, also known as “air-hardening” or “cold work” steel, is a prime example of material science at its finest. Its composition, which includes chromium, carbon, and manganese, imparts exceptional toughness and wear resistance—qualities that are highly sought after in precision engineering.

Achieving Microstructural Excellence

One of the defining characteristics of A2 steel is its ability to achieve a refined microstructure through heat treatment. This allows manufacturers to fine-tune the material’s mechanical properties to suit specific applications, a crucial aspect of precision engineering.

Applications in Precision Engineering

Tool and Die Manufacturing

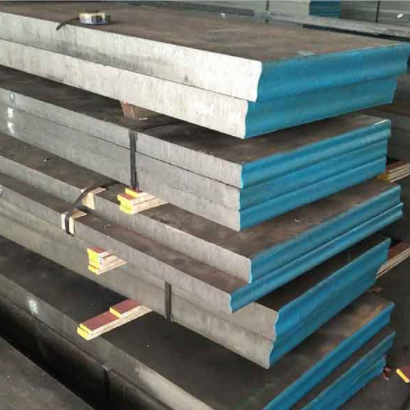

A2 steel has found its niche in tool and die manufacturing, where durability, wear resistance, and precision are paramount. It’s the preferred choice for creating punches, dies, and cutting tools that need to maintain their performance over prolonged usage.

Injection Molding

In the field of injection molding, where intricate molds are essential for producing complex parts, A2 steel’s combination of toughness and machinability shines. It ensures that molds remain dimensionally stable and resistant to wear, ensuring the production of high-quality components.

Fine Mechanical Components

From gears and bearings to shafts and precision parts in mechanical assemblies, A2 steel plays a crucial role in maintaining the integrity of intricate mechanisms. Its ability to endure repeated stress and retain its shape makes it an invaluable asset.

Precision Engineering and Beyond

A2 Steel’s Contribution to Innovation

The use of A2 steel extends beyond traditional manufacturing. It paves the way for innovations in areas such as medical devices, where precision is essential for patient care, and in electronics, where miniaturization demands materials that can maintain their properties on a microscale.

In the realm of precision engineering, A2 steel emerges as a true game-changer. Its exceptional properties, combined with its versatility and reliability, make it an indispensable material for industries that demand accuracy and performance. As precision engineering continues to shape our world, A2 steel stands as a testament to the vital role materials play in driving innovation.