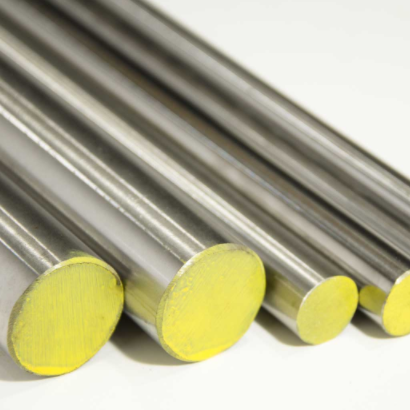

A2 steel is classified as an air-hardening tool steel, primarily composed of iron, carbon, chromium, molybdenum, and vanadium. This composition is carefully balanced to create a steel that can withstand demanding cutting tasks while maintaining its edge.

A2 Steel Properties: Balancing Hardness and Toughness

The distinctive feature of A2 steel lies in its ability to strike a balance between hardness and toughness. It offers a high level of hardness that ensures excellent edge retention, while its toughness prevents the blade from chipping or breaking during use.

Heat Treatment and Blade Performance

The heat treatment process is pivotal in harnessing the full potential of A2 steel. Proper heat treatment enhances its hardness and toughness, optimizing the blade’s performance for various cutting applications.

Advantages of A2 Steel for Knives

Excellent Edge Retention

A2 steel’s fine grain structure and high carbon content contribute to its impressive edge retention. This means the blade can maintain its sharpness even after extended use.

High Wear Resistance

The wear resistance of A2 steel ensures that the blade remains effective against abrasive materials, making it suitable for tasks that involve tough cutting conditions.

Ease of Sharpening

While A2 steel retains its edge well, it’s also relatively easy to sharpen. This convenience is appreciated by users who want to maintain their blade’s performance with minimal effort.

Corrosion Resistance

Although not completely stainless, A2 steel exhibits a level of corrosion resistance due to its chromium content. Proper care and maintenance can help mitigate corrosion risks.

A2 Steel in Knife Manufacturing

Chef’s Knives

A2 steel’s combination of edge retention and easy sharpening makes it a favorite for chef’s knives. Culinary professionals value its ability to handle precision cutting tasks in the kitchen.

Hunting and Outdoor Knives

In hunting and outdoor scenarios, A2 steel’s durability and edge retention prove invaluable. It’s capable of handling various cutting tasks, from field dressing to wood processing.

Woodworking Tools

A2 steel’s toughness and wear resistance make it an ideal choice for woodworking tools. Chisels and plane blades crafted from A2 steel retain their sharpness even when used on hardwoods.

Maintaining and Caring for A2 Steel Knives

To prolong the life of A2 steel knives, regular cleaning, drying, and occasional oiling are recommended. Proper storage and avoiding exposure to corrosive substances also contribute to longevity.

Comparing A2 Steel to Other Knife Steels

A2 steel falls within the category of high-carbon tool steels, distinguishing it from stainless steels. Its unique properties make it suitable for specific applications where hardness and toughness are paramount.

The A2 Steel Experience: Cutting and Slicing

Using an A2 steel knife is a gratifying experience. The blade effortlessly cuts through various materials, showcasing its edge retention and overall cutting prowess.

A2 steel’s remarkable blend of hardness, toughness, and edge retention has established it as a preferred choice for knife enthusiasts and professionals alike. Its versatile properties make it an asset in various cutting tasks, from culinary arts to outdoor adventures.