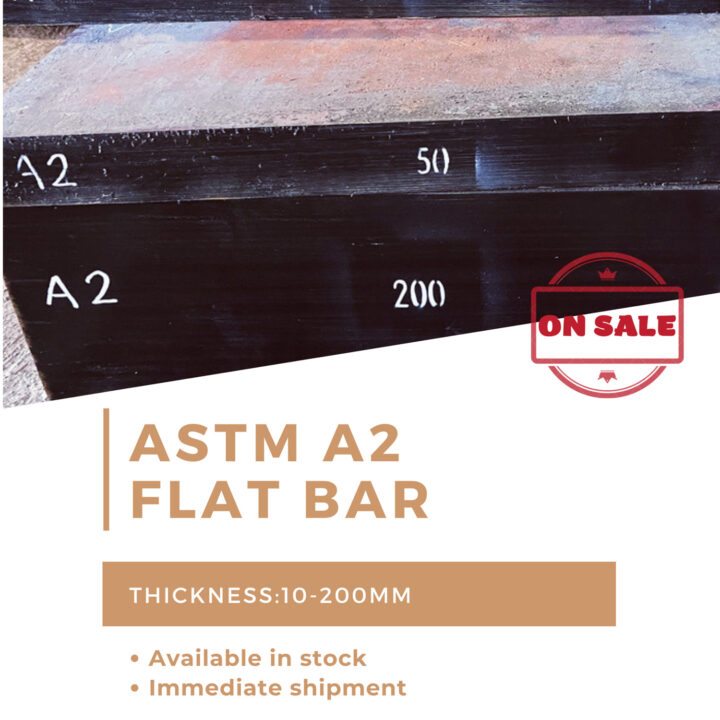

Plate quenching is a heat treatment method designed to rapidly cool steel, inducing specific changes in its microstructure to enhance its properties. When applied to A2 steel, a high-carbon, high-chromium tool steel, plate quenching imparts remarkable hardness and wear resistance.

The Science Behind A2 Steel

A2 steel is characterized by its composition, which typically includes:

- Carbon (C): 0.95% – 1.05%

- Chromium (Cr): 4.75% – 5.50%

- Molybdenum (Mo): 0.90% – 1.40%

- Vanadium (V): 0.15% – 0.50%

This composition contributes to A2 steel’s excellent toughness, wear resistance, and ability to retain its shape at high temperatures.

The Plate Quenching Process

The plate quenching process involves carefully heating the A2 steel to its critical transformation temperature and then rapidly cooling it by placing it between two metal plates. This rapid cooling, or quenching, results in the formation of a fine-grained microstructure that enhances the steel’s hardness and wear resistance.

Benefits of Plate Quenching A2 Steel

- Hardness: Plate quenching significantly increases the hardness of A2 steel, making it suitable for applications requiring cutting and machining.

- Wear Resistance: The process enhances the steel’s wear resistance, ensuring it can withstand abrasive environments.

- Toughness: Despite its hardness, plate-quenched A2 steel retains a certain level of toughness, reducing the risk of brittle fractures.

- Dimensional Stability: The microstructure formed during plate quenching contributes to the steel’s dimensional stability even under varying temperatures.

Applications and Industries

Plate-quenched A2 steel finds application in various industries:

- Tool and Die Making: Its exceptional hardness and wear resistance make it ideal for tool and die manufacturing.

- Cutting Tools: Blades, punches, and cutting tools benefit from the steel’s enhanced properties.

- Woodworking Tools: A2 steel is used in making chisels, plane blades, and other tools used in woodworking.

Challenges and Considerations

- Warpage: Rapid cooling during quenching can lead to warping or distortion of the steel.

- Cracking: Improper quenching can result in cracks due to the high internal stresses.

- Uniformity: Ensuring uniform cooling across the entire plate is essential to achieve consistent properties.

Ensuring Quality and Precision

To ensure quality and precision in plate quenching A2 steel, factors such as temperature control, quenching medium, and cooling rate must be meticulously managed.

Innovations in Heat Treatment

Advancements in heat treatment technology continue to refine the plate quenching process, leading to even more controlled and precise results.

Plate quenching A2 steel is a refined heat treatment process that elevates the properties of this specialized steel. Its ability to impart enhanced hardness, wear resistance, and toughness makes it a vital technique in industries that demand precision and durability.