30CrNiMo8 is a low-alloy steel known for its exceptional strength, toughness, and hardenability. It belongs to the group of nickel-chromium-molybdenum steels, which are renowned for their high-performance characteristics. This steel is primarily used in applications requiring high tensile and yield strength. (30CrNiMo8 Equivalent Material)

Properties of 30CrNiMo8 Steel

Mechanical Properties

30CrNiMo8 steel exhibits remarkable mechanical properties, making it suitable for a range of engineering applications. Some key mechanical properties include:

- Tensile Strength: Typically ranging from 800 to 1100 MPa, indicating its high tensile capacity.

- Yield Strength: Approximately 600 MPa, providing good resistance to deformation.

- Elongation: About 13% to 18%, indicating its ductility.

- Impact Toughness: Excellent impact resistance, especially at low temperatures.

Chemical Composition

The chemical composition of 30CrNiMo8 steel includes the following key elements:

- Carbon (C): Approximately 0.26% to 0.34%, contributing to hardness and strength.

- Chromium (Cr): Around 1.8% to 2.2%, enhancing corrosion resistance.

- Nickel (Ni): Comprising 1.8% to 2.2%, adding toughness and impact resistance.

- Molybdenum (Mo): Approximately 0.25% to 0.35%, improving strength and hardenability.

Applications of 30CrNiMo8 Steel

30CrNiMo8 steel finds its application in various industries, including:

- Automotive: Commonly used for components like crankshafts and gears due to its high strength.

- Aerospace: Utilized in aircraft landing gear and structural components.

- Manufacturing: Suitable for producing heavy-duty machinery parts.

- Oil & Gas: Used in the construction of drilling equipment.

30CrNiMo8 Equivalent Material – AISI 4340

When searching for equivalent materials to 30CrNiMo8 steel, one alloy that stands out is AISI 4340. Let’s explore the similarities and differences between these two alloys.

Comparison with AISI 4340

AISI 4340 is another high-strength, low-alloy steel with properties similar to 30CrNiMo8. Both alloys share these characteristics:

- High tensile and yield strength.

- Good toughness and impact resistance.

- Suitable for applications in aerospace, automotive, and manufacturing industries.

Manufacturing Process

The production of 30CrNiMo8 steel involves a series of manufacturing steps, including melting, casting, hot rolling, and heat treatment. These processes are meticulously controlled to achieve the desired mechanical properties.

Heat Treatment

Heat treatment is a critical step in enhancing the properties of 30CrNiMo8 steel. The alloy is typically quenched and tempered to achieve the desired hardness and toughness.

Machinability

30CrNiMo8 steel exhibits good machinability, allowing for the production of complex parts with precision.

Weldability

This alloy has moderate weldability, although preheating and post-weld heat treatment may be required for certain applications.

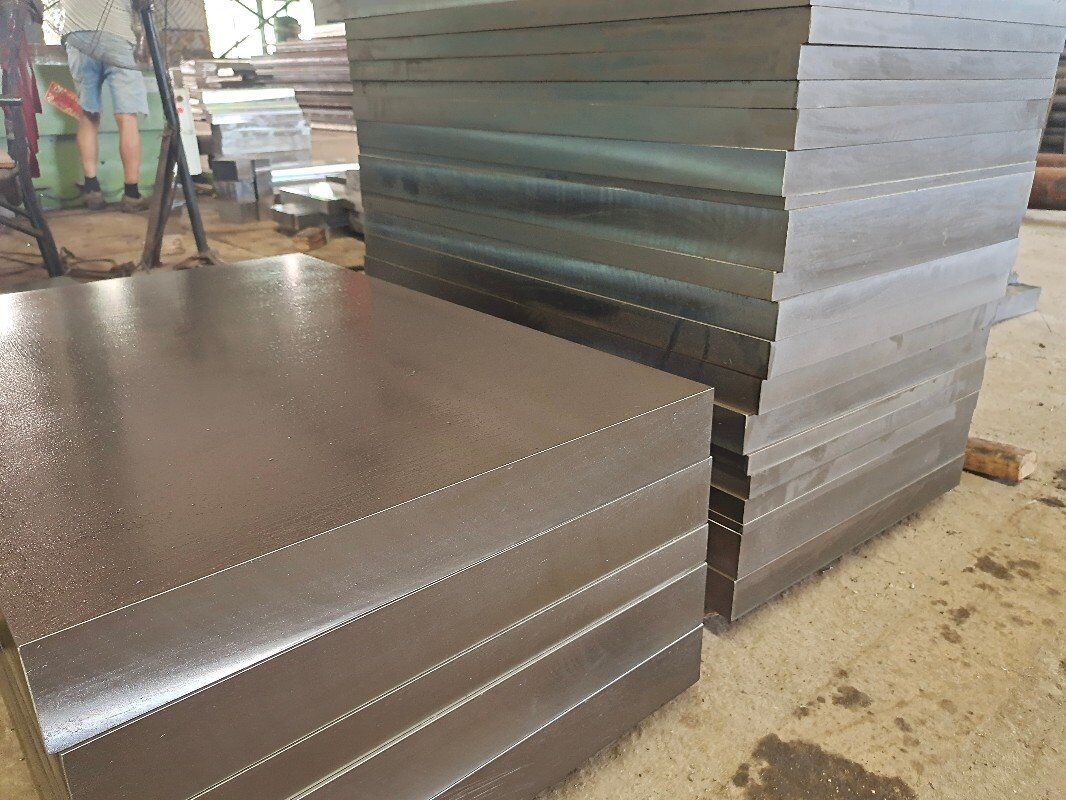

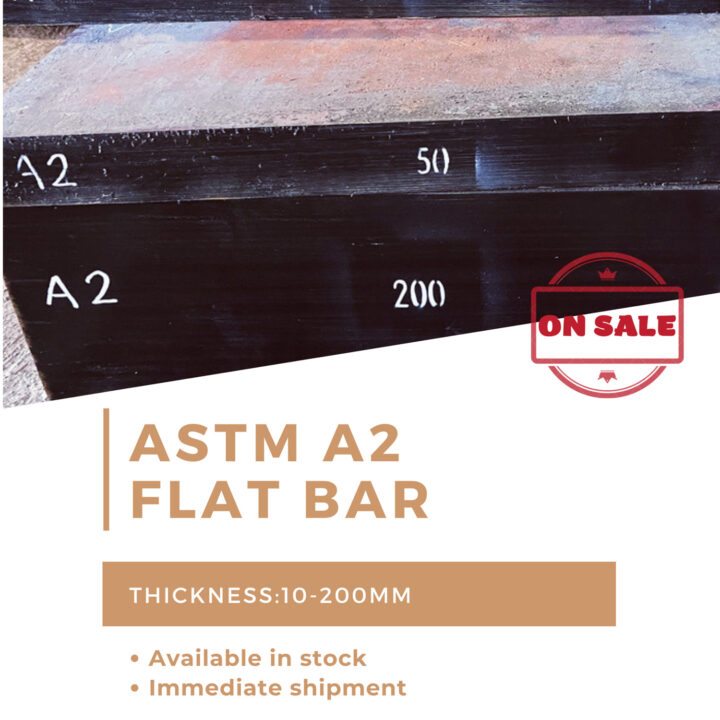

Availability in the Market

30CrNiMo8 steel is readily available in various forms, including bars, sheets, and forged components. It is commonly used by manufacturers and is accessible through steel suppliers.