Optimizing 30CrNiMo8 Alloy Through Heat Treatment

Optimizing 30CrNiMo8 Alloy Through Heat Treatment

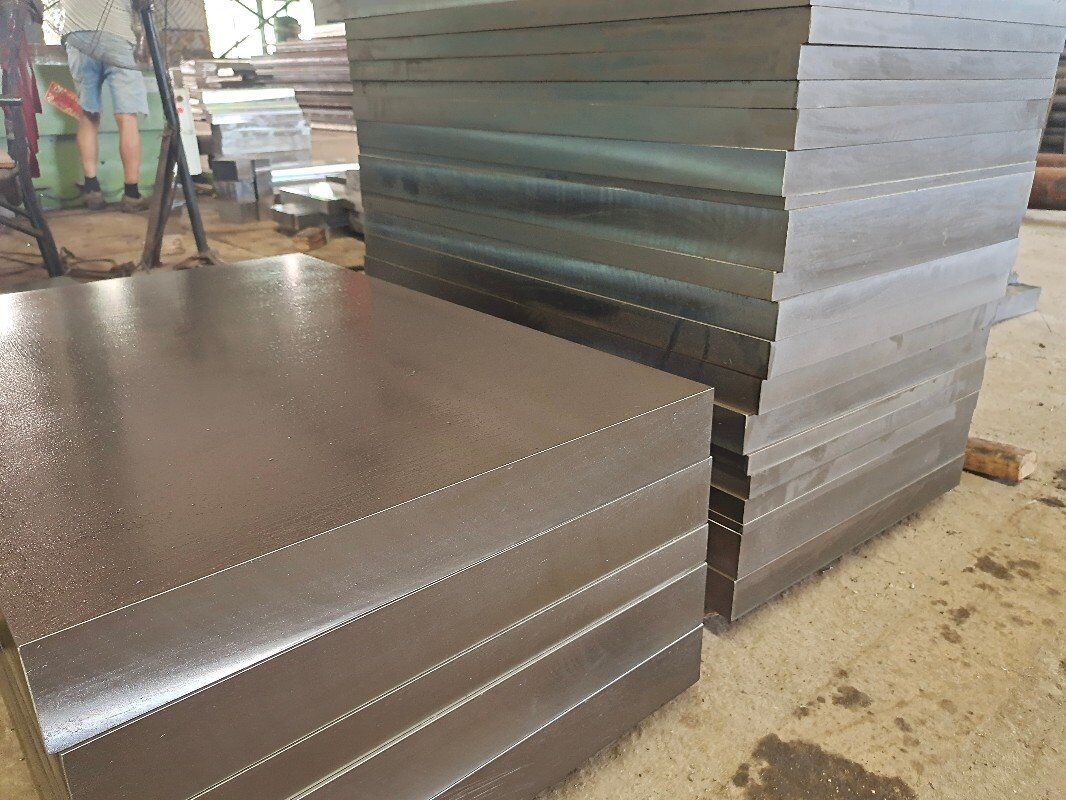

Before we embark on the intricacies of heat treatment, let’s acquaint ourselves with the star of our show—the 30CrNiMo8 alloy. Composed of chromium, nickel, and molybdenum, this alloy is renowned for its exceptional strength and durability, making it a prime choice in demanding applications across various industries.

The Power of Heat: A Metamorphosis Begins

30CrNiMo8 Alloy’s Response to Heat

The process of optimizing 30CrNiMo8 alloy begins with heat treatment, a metamorphosis that takes this alloy from its raw form to a state of enhanced strength and resilience. Heat treatment involves controlled heating and cooling cycles, strategically applied to unlock the alloy’s full potential.

Tempering: Balancing Strength and Toughness

Understanding the Art of Tempering

Tempering, a crucial step in the heat treatment process, aims to strike a delicate balance between strength and toughness. By reheating the alloy to a specific temperature and then cooling it, tempering refines the microstructure, ensuring the alloy possesses the desired combination of hardness and ductility.

Quenching: Rapid Cooling for Maximum Strength

The Quenching Process Decoded

Quenching, the rapid cooling phase of heat treatment, is where the magic happens. By plunging the heated 30CrNiMo8 alloy into a quenching medium, such as oil or water, the molecular structure undergoes a rapid transformation. This process instills maximum hardness, setting the stage for a material that can withstand intense mechanical stress.

Annealing: Enhancing Machinability and Reducing Residual Stresses

Unlocking the Secrets of Annealing

Annealing, the gentle giant of heat treatment, involves slow cooling to relieve internal stresses and improve machinability. This process refines the grain structure of the alloy, reducing brittleness and enhancing its overall workability.

Case Hardening: Elevating Surface Hardness

A Closer Look at Case Hardening

For applications where surface hardness is paramount, case hardening becomes a valuable technique. By infusing carbon into the surface layers of the 30CrNiMo8 alloy and subjecting it to heat treatment, a hardened exterior is achieved while maintaining a tough core.

Precision Control: Tailoring Heat Treatment for Desired Properties

The Art of Customization

One of the remarkable features of optimizing 30CrNiMo8 alloy through heat treatment lies in the ability to customize its properties. By precisely controlling temperature and duration at each stage, manufacturers can tailor the alloy to meet specific requirements, ensuring it performs optimally in diverse applications.

Challenges and Considerations in Heat Treatment

Navigating the Heat Treatment Landscape

While heat treatment is a transformative process, challenges may arise. Achieving uniform heating, avoiding excessive distortion, and addressing the risk of quench cracking are considerations that demand careful attention. Navigating these challenges ensures the alloy realizes its full potential.

Real-World Applications: Where Optimized 30CrNiMo8 Alloy Shines

From Industrial Machinery to Automotive Components

The optimized 30CrNiMo8 alloy finds its place in the sun across a spectrum of real-world applications. Whether as a vital component in industrial machinery subjected to heavy loads or as a high-performance gear in automotive transmissions, the alloy’s enhanced properties shine in demanding environments.