Heat Treatment Process for 30CrNiMo8 Material

Heat Treatment Process for 30CrNiMo8 Material

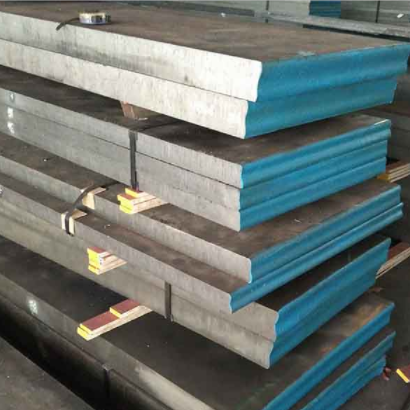

Steel, a versatile material, often undergoes various processes to enhance its properties, and 30CrNiMo8 is no exception. Heat treatment, a critical step in the manufacturing journey, plays a pivotal role in refining the characteristics of this alloy. In this exploration, we’ll delve into the intricate details of the heat treatment process for 30CrNiMo8 material, unraveling the steps that transform raw steel into a robust and reliable engineering component.

Understanding the Foundation: Composition of 30CrNiMo8

Before delving into the heat treatment process, let’s revisit the foundation—30CrNiMo8’s composition. This alloy, enriched with chromium, nickel, and molybdenum, forms the base for its exceptional mechanical properties. The composition sets the stage for a heat treatment journey that enhances the alloy’s strength, toughness, and wear resistance.

Step 1: Heating the Alloy – The Beginnings of Transformation

The heat treatment process for 30CrNiMo8 kicks off with controlled heating. The alloy undergoes gradual heating to a specific temperature, often ranging between 850°C to 1050°C, depending on the desired properties. This initial phase aims to homogenize the material, ensuring a uniform distribution of its alloying elements.

Step 2: Soaking – Allowing the Heat to Penetrate

Once the alloy reaches the predetermined temperature, it enters the soaking phase. This involves maintaining the steel at that temperature for a specified duration. This period of soaking allows the heat to penetrate the entire mass of the material, ensuring a thorough transformation of its microstructure.

Step 3: Quenching – Rapid Cooling for Hardening

Following the soaking phase, quenching takes center stage. This is a rapid cooling process that involves immersing the heated alloy into a quenching medium, typically oil, water, or polymer solutions. The sudden cooling induces a phase transformation, leading to the hardening of the material. Quenching determines the hardness of the final product, with varying cooling rates yielding different results.

Step 4: Tempering – Balancing Hardness and Toughness

Hardening is not the end of the story. The tempered steel undergoes a crucial step called tempering. During this phase, the material is reheated to a specific temperature, and it is then allowed to cool at a controlled rate. Tempering imparts additional toughness to the alloy, striking a delicate balance between hardness and resilience. The choice of tempering temperature influences the final mechanical properties of 30CrNiMo8.

Step 5: Stress Relieving – Minimizing Internal Stresses

To minimize internal stresses that may have developed during the heat treatment process, the material undergoes stress relieving. This involves heating the alloy to a temperature below its transformation range and allowing it to cool gradually. Stress relieving enhances the dimensional stability of the material, making it more predictable in subsequent manufacturing processes.

Step 6: Inspection and Quality Assurance – Ensuring Precision

The heat-treated 30CrNiMo8 material undergoes rigorous inspection and quality assurance measures. This includes checking for dimensional accuracy, hardness, and microstructural integrity. Quality control ensures that the material meets or exceeds industry standards, guaranteeing reliable performance in real-world applications.

Step 7: Application-Specific Treatment – Tailoring Properties

In some cases, additional treatments may be applied to further tailor the properties of 30CrNiMo8 for specific applications. This could include carburizing or nitriding processes, which enhance surface hardness and wear resistance. These supplementary treatments cater to the unique demands of diverse industries.

Step 8: Final Machining and Finishing – Crafting the End Product

The heat-treated 30CrNiMo8 material moves to the final stages of production, involving machining and finishing processes. Machining requires finesse to shape the material accurately, considering its enhanced hardness. Finishing ensures a smooth surface, contributing to both aesthetics and functionality.

Conclusion

In conclusion, the heat treatment process for 30CrNiMo8 material is a symphony of controlled heating, soaking, quenching, tempering, stress relieving, inspection, and application-specific treatments. Each step contributes to transforming raw steel into a material that embodies strength, toughness, and wear resistance. The meticulous orchestration of these processes ensures that 30CrNiMo8 stands ready to meet the challenges of diverse engineering applications.