A2 Steel in Tool and Blade Manufacturing

A2 Steel in Tool and Blade Manufacturing

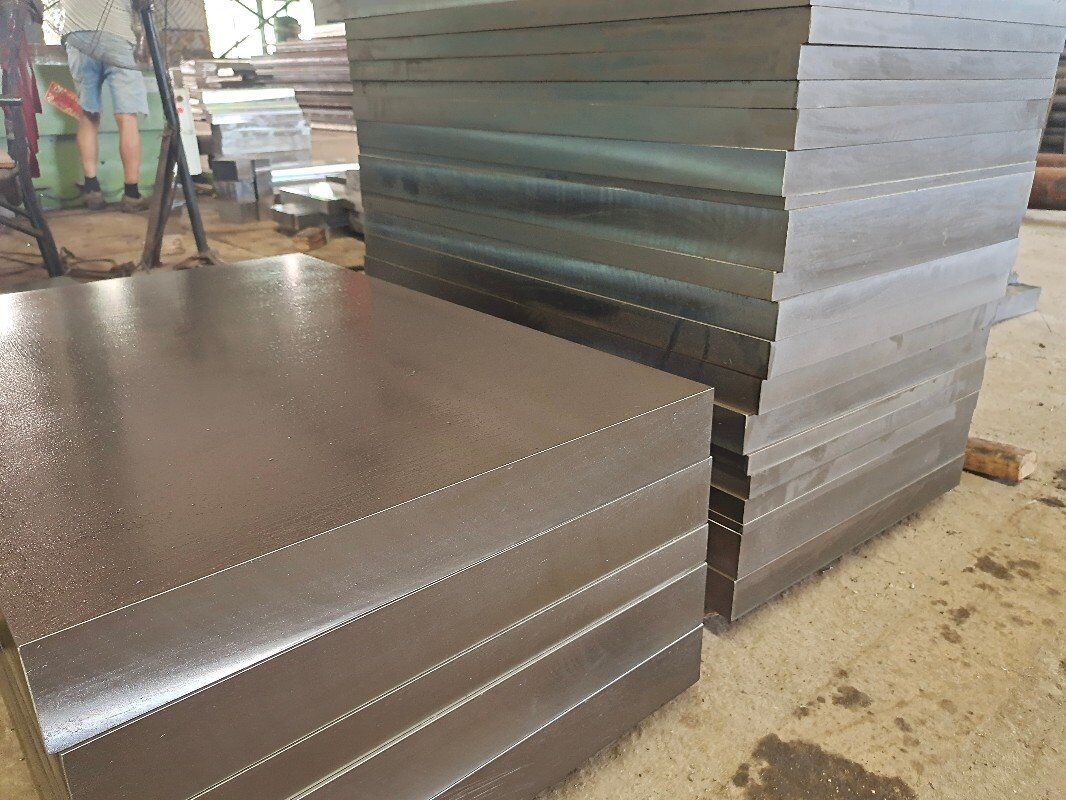

At the core of A2 steel’s brilliance lies its unique composition. Comprising carbon, chromium, molybdenum, and vanadium, A2 steel forms a fine-grained microstructure. It sets the stage for exceptional wear resistance and toughness. This composition makes it a standout choice for tools and blades requiring precision and durability.

Crafting Precision: Tools For the Trade

In the hands of skilled artisans and manufacturers, A2 steel transforms into high-precision cutting tools. The alloy’s ability to maintain a sharp edge, resist wear, and endure the demands of machining processes. This makes it an ideal candidate for applications ranging from milling cutters to precision gauges. The craftsmanship involved in creating these tools ensures that A2 steel’s inherent properties are harnessed to their full potential.

Forging Excellence: Blades Beyond the Ordinary

Blades are not mere instruments; they are extensions of artistry and functionality. A2 steel, with its resistance to deformation during forging, becomes the canvas upon which master bladesmiths create works of functional art. From chef’s knives to hunting blades, A2 steel blades offer a blend of sharpness, toughness, and corrosion resistance that elevates them above the ordinary.

Precision Cuts and Beyond: A2 Steel in Woodworking Tools

Woodworkers understand the importance of precision in every cut. A2 steel, with its ability to hold a keen edge, finds a natural home in woodworking tools. Chisels, plane blades, and carving tools made from A2 steel not only deliver accuracy but also endure the rigors of shaping and refining wood with finesse.

The Art of Machining: A2 Steel at the Lathe and Mill

In the world of machining, where precision is paramount, A2 steel emerges as a reliable companion. Its machinability, when combined with the right cutting tools and techniques, allows for the creation of intricate components. Whether at the lathe or the mill, A2 steel’s versatility shines through, providing machinists with a material that responds to their craft with precision and ease.

The Crucial Role of Heat Treatment in Blade Manufacturing

Behind every exceptional blade lies a carefully orchestrated dance of heat and steel. A2 steel’s air-hardening nature demands a meticulous approach to heat treatment. Bladesmiths carefully heat the steel to specific temperatures, quench it in the air, and then temper it to achieve the desired hardness. This process, akin to a blacksmith’s alchemy, imparts the blade with strength and resilience.

The Bonding Process: Welding A2 Steel for Structural Integrity

Crafting multi-part tools or blades often involves the art of welding. A2 steel, with its composition and properties, can be welded to create complex structures without sacrificing its integrity. Welders skilled in the nuances of working with A2 steel ensure that the welded joints maintain the material’s strength and durability.

The Finishing Touch: Surface Treatment for Enhanced Performance

A2 steel, though formidable on its own, often undergoes surface treatments to enhance its performance. Polishing, coating, or nitriding – each method serves a specific purpose. Whether it’s improving corrosion resistance or adding an extra layer of hardness, these finishing touches complete the journey of A2 steel from raw material to a tool or blade ready for action.

Conclusion

In the symphony of tools and blades, A2 steel plays a leading role, offering a harmonious blend of precision, durability, and craftsmanship. From the hands of artisans to the machines of manufacturers, the journey of A2 steel involves a deep understanding of its composition. The art of heat treatment, and the finesse required in crafting tools that stand the test of time.