A2 alloy steel-Unleashing the Potential of A2 Steel

In the world of steel alloys, A2 steel stands out as a versatile and reliable material. If you’re on the hunt for A2 steel but are unsure about its standard, properties, and where to find the best supplier. You’ve come to the right place. Let’s dive into the nuances of A2 steel, exploring its standard, chemical composition, applications, sizes, and prices. And how to navigate the market to source this exceptional material.

Decoding A2 Steel: A Brief Overview

Standard and Composition: The Blueprint of Excellence A2 steel adheres to the AISI (American Iron and Steel Institute) standard, specifically falling under the air-hardening tool steel category. Its chemical composition includes 1.00% carbon, 5.25-6.75% chromium, 0.90-1.40% manganese, and 0.90-1.20% molybdenum. This combination results in a steel alloy renowned for its wear resistance and toughness.

Applications: Where A2 Steel Thrives

Versatility in Action: From Blades to Tooling A2 steel finds its footing in various applications. Its excellent wear resistance, combined with good toughness, makes it a favorite for creating industrial knives, blanking dies, and forming tools. Additionally, it’s a top choice for punches, shear blades, and intricate molding applications.

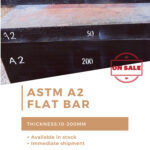

Sizes and Shapes: Tailoring to Your Needs

A2 Steel Dimensions: Matching Your Project Requirements Manufacturers offer A2 steel in various sizes and shapes, catering to the diverse needs of industries. Rounds, flats, and squares are common forms, ensuring flexibility for different machining and design demands.

A2 Steel Hardness: The Measure of Strength

Rockwell Hardness: A2’s Forte One of the standout features of A2 steel is its impressive hardness. With a typical Rockwell hardness ranging from 60-62 HRC after heat treatment, it ensures durability and edge retention. Making it an ideal choice for cutting tools and blades.

Navigating the Market: Understanding A2 Steel Prices

Pricing Dynamics: Balancing Quality and Cost The cost of A2 steel can vary based on factors such as market demand, supplier reputation, and order quantities. A thorough market analysis is essential to secure competitive rates without compromising on quality.

Sourcing Strategies: Finding Your Ideal Supplier

Supplier Vetting: Certifications and Reputation Sourcing A2 steel involves partnering with a reputable supplier. Look for certifications, transparent communication, and a proven track record. These factors ensure that the material you receive meets the highest standards.

Conclusion: Unleashing the Potential of A2 alloy steel

In conclusion, A2 steel is a powerhouse in the world of tool steels, offering a balance of hardness, toughness, and wear resistance. Armed with knowledge about its standard, composition, and applications, you can confidently explore the possibilities that A2 steel brings to your projects.