Amidst the array of materials available, A2 alloy steel emerges as a true contender, admired for its unique combination of qualities. From its applications in toolmaking to its contributions in shaping various products, A2 alloy steel continues to influence industries through its outstanding attributes.

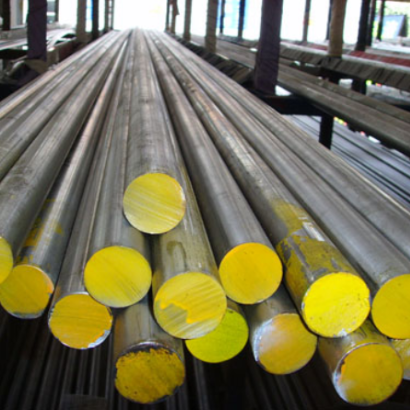

Understanding A2 Alloy Steel Composition

At its core, A2 alloy steel is a chromium-based tool steel. It typically contains around 1% carbon, along with significant amounts of chromium and molybdenum. This composition not only provides A2 with impressive hardness but also contributes to its ability to be hardened through air cooling.

The Power of Toughness and Wear Resistance

One of the most notable characteristics of A2 alloy steel is its remarkable toughness and wear resistance. This attribute makes it an excellent choice for applications that involve high impact forces and abrasive conditions. A2 alloy steel can retain its sharpness and withstand deformation, crucial qualities for toolmaking.

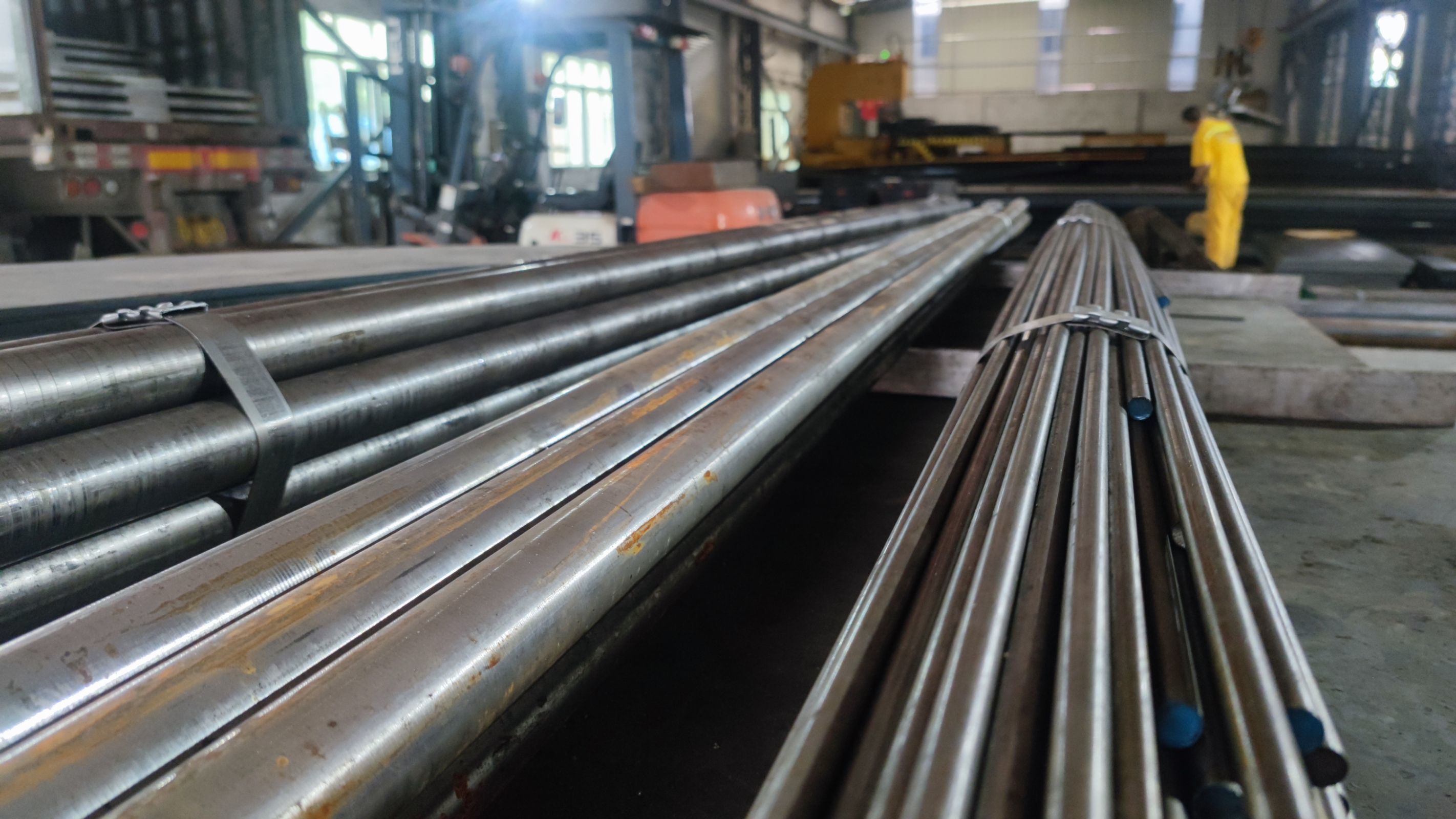

A2 Alloy Steel’s Role in Toolmaking

The realm of toolmaking benefits significantly from A2 alloy steel. From cutting tools to forming dies, punches, and even woodworking tools, A2’s combination of hardness and toughness allows for precision and durability, translating into longer tool life and enhanced productivity.

Applications Beyond Tools: A2 in Various Industries

Beyond toolmaking, A2 alloy steel finds applications in diverse industries. It plays a role in the production of components that require a balance between hardness and machinability. Examples include machinery parts, automotive components, and even certain types of industrial knives.

Achieving Optimal Performance Through Heat Treatment

The heat treatability of A2 alloy steel is a crucial aspect of its application. Proper heat treatment enables the steel to attain its desired hardness and other mechanical properties. This process involves heating, quenching, and tempering, resulting in the fine-tuning of the steel’s performance.

Challenges and Considerations When Working with A2 Alloy Steel

While A2 alloy steel offers numerous advantages, it requires careful attention during forging, machining, and heat treatment processes. Improper practices can lead to issues such as overheating, which might affect the steel’s properties and performance.

Environmental Sustainability: A2 Steel’s Green Advantage

In the context of sustainable manufacturing, A2 alloy steel presents an advantage due to its potential for reconditioning and repurposing. The ability to extend the lifespan of tools reduces the need for frequent replacements, contributing to a more environmentally friendly approach.

A2 alloy steel encapsulates the spirit of innovation and versatility in materials engineering. Its unique composition and outstanding properties enable applications across industries, from crafting precision tools to enhancing the performance of various components. As industries continue to evolve, A2 alloy steel remains a steadfast companion in the journey of progress.