a2 material mechanical properties: Engineered for Performance

a2 material mechanical properties: Engineered for Performance

Introduction

In the realm of industrial manufacturing, the mechanical properties of materials are paramount in determining product performance. A2 alloy steel exemplifies meticulous engineering tailored to meet the rigorous demands across various industries. This article explores the comprehensive mechanical properties of A2 material, shedding light on its industrial applications and the pivotal role these properties play in ensuring project success.

Introduction to A2 Material

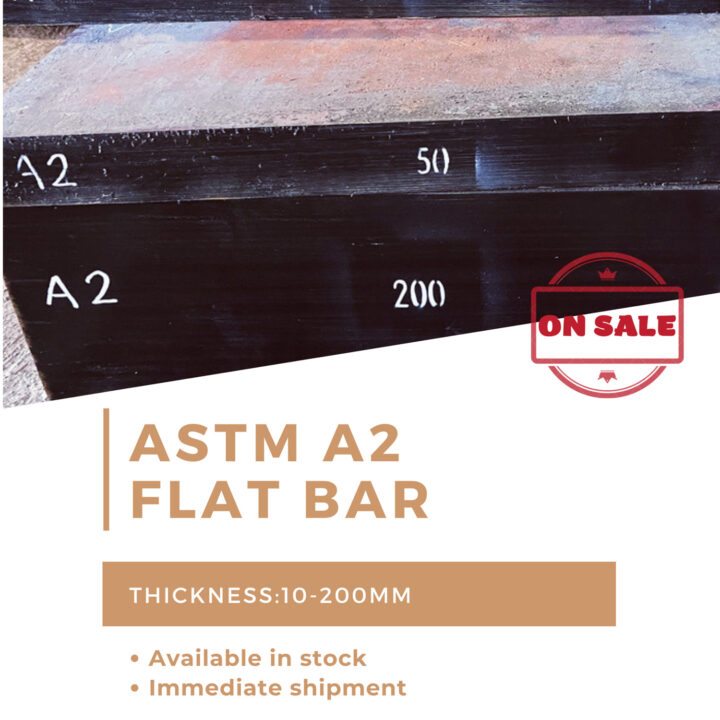

A2 alloy steel, a distinguished high-carbon, high-chromium tool steel, boasts a robust array of mechanical properties. Comprising elements such as carbon, chromium, and molybdenum, A2 steel blends strength, hardness, and exceptional wear resistance. These attributes render it a preferred choice where reliability and durability are non-negotiable.

Tensile and Yield Strength

A2 steel’s tensile strength surpasses 1000 MPa, showcasing its ability to withstand substantial pulling forces without yielding. This characteristic is crucial in demanding applications like automotive components and heavy machinery. Meanwhile, its high yield strength ensures structural integrity under load, a vital attribute for critical applications.

Hardness and Ductility

The remarkable hardness of A2 steel, reaching up to 65 HRC, underscores its resistance to deformation—a critical feature in applications prioritizing wear resistance, such as cutting tools and dies. Balancing this hardness is its sufficient ductility, enabling it to deform under stress without fracturing, meeting diverse manufacturing needs.

Impact and Fatigue Resistance

In environments subject to cyclic loading, A2 steel’s superior fatigue resistance ensures prolonged service life without failure, making it ideal for components like springs and bearings. Additionally, its capacity to absorb energy during impacts enhances its suitability for applications where sudden mechanical stresses are prevalent, such as automotive suspension systems.

Mechanical Testing and Standards

To guarantee adherence to stringent industrial requirements, A2 steel undergoes rigorous mechanical testing. Standards like ASTM A686 and ISO 4957 specify parameters for properties such as tensile strength, yield strength, hardness, and impact resistance. These tests uphold consistency and reliability in every batch of A2 steel produced.

Applications in Engineering and Manufacturing

A2 steel’s versatile mechanical properties position it prominently in engineering and manufacturing sectors. Widely utilized in cutting tools, dies, and molds due to its hardness and wear resistance, it also finds application in automotive components like gears and transmission parts, where strength and durability are paramount. In aerospace, A2 steel’s properties ensure reliability in parts exposed to extreme conditions such as high temperatures and pressures.

Case Studies

A notable automotive case study highlights A2 steel’s deployment in engine components, where its high tensile and yield strength enhanced reliability and reduced maintenance costs in high-performance engines. Similarly, in aerospace, A2 steel’s fatigue resistance played a critical role in designing durable aircraft landing gear components, ensuring safety and longevity.

a2 material mechanical properties: Engineered for Performance

In conclusion, A2 material’s mechanical properties distinguish it as a preferred choice across diverse industrial applications. Its blend of strength, hardness, ductility, and resilience to impact and fatigue underscores its reliability and versatility. As industrial demands evolve, understanding and leveraging A2 material’s mechanical properties will continue to be pivotal. Companies specializing in high-performance materials, like OTAI, exemplify this focus, delivering products that consistently exceed client expectations through meticulous attention to these critical attributes.