A2 steel annealed hardness-A2 Steel in its Annealed State

A2 steel annealed hardness-A2 Steel in its Annealed State

A2 steel, known for its exceptional qualities, reveals a different facet when in its annealed state. In this guide, we’ll explore the annealed hardness of A2 steel, shedding light on its standard, chemical composition, applications, sizes, pricing, and sourcing avenues. Whether you’re a bladesmith, engineer, or enthusiast, understanding A2 steel in its annealed form is a journey worth taking.

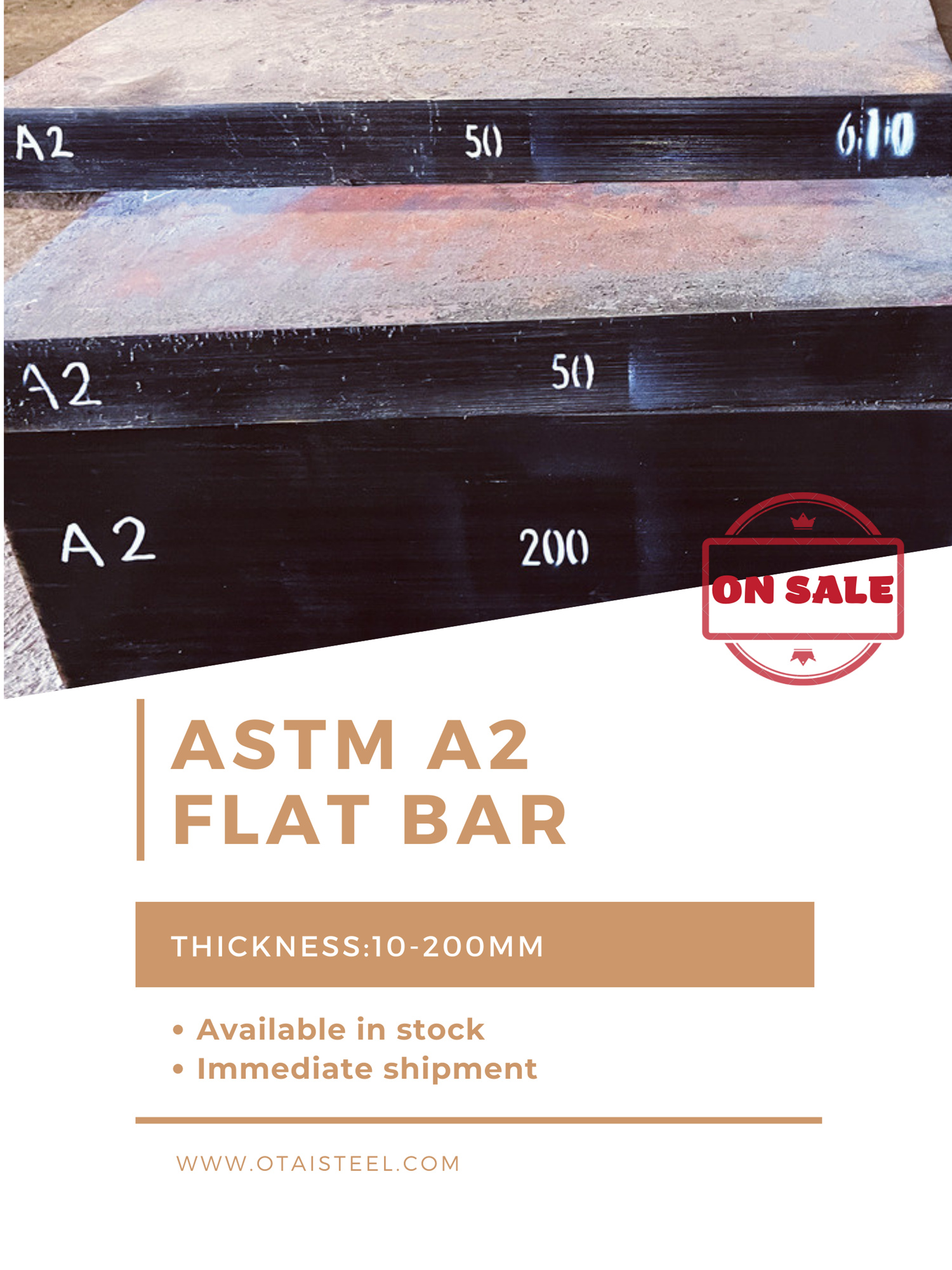

Deciphering the Standard: A2 Steel’s Unwavering Foundation

Standard Insights

At the core of A2 steel lies a commitment to industry standards. Governed by the ASTM A681 standard, A2 steel ensures uniformity and quality, setting the stage for its remarkable performance in various applications.

Breaking Down Composition: The Symphony of A2 Steel

Chemical Composition Insights

Understanding the chemical composition of A2 steel is crucial in comprehending its annealed state. With a harmony of carbon, chromium, vanadium, and other elements, A2 steel in its annealed form exhibits a balance that contributes to its machinability, toughness, and ease of fabrication.

Applications Unleashed: A2 Steel’s Versatility Unveiled

Versatile Applications

While the focus here is on the annealed state, it’s essential to appreciate the wide range of applications A2 steel caters to. From crafting precision tools to manufacturing intricate parts, A2 steel’s versatility remains a constant, irrespective of its state.

Annealed Hardness: Understanding the Soft Side of A2 Steel

Annealing Process

Annealing involves heating A2 steel to a specific temperature and then slowly cooling it. In its annealed state, A2 steel achieves a softer hardness, typically ranging between 200 and 225 Brinell hardness. This state is optimal for machining, forming, and subsequent heat treatments.

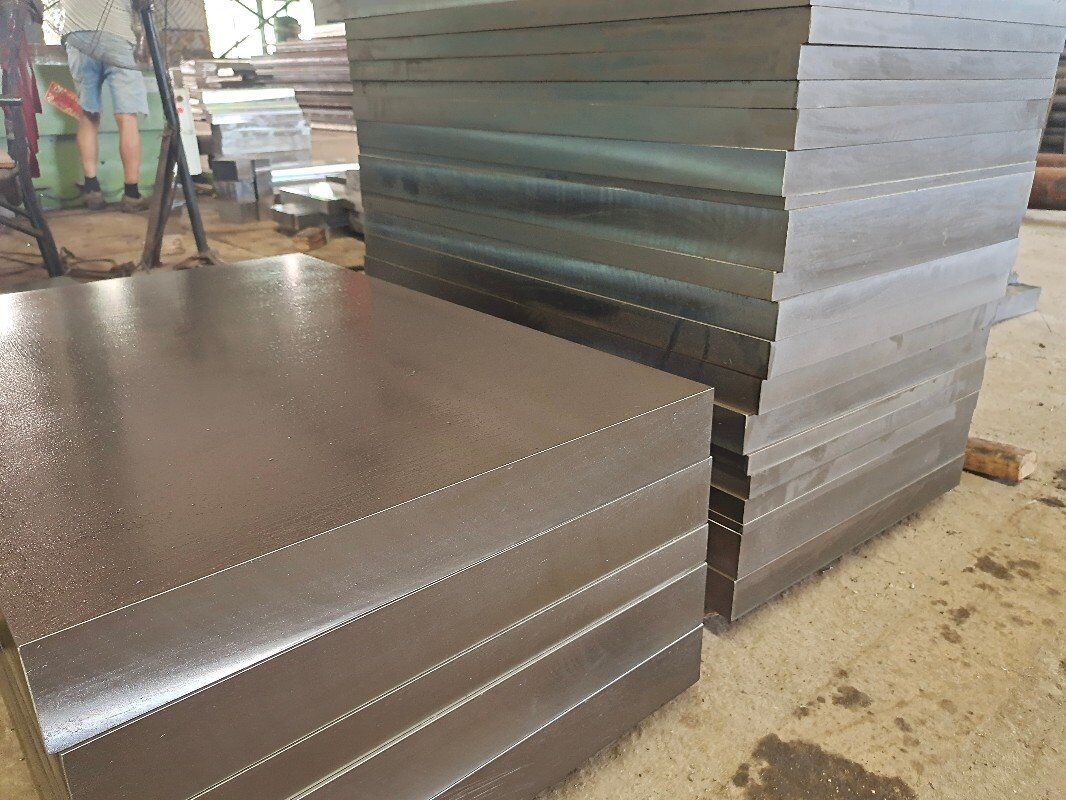

Size Matters: Tailoring Annealed A2 Steel to Your Needs

Sizing Options Explored

Consider the size of your A2 steel during the annealing process. Whether you’re working with large bars or intricate components, annealing allows for uniform softening, ensuring ease of further processing.

Counting the Cost: Navigating A2 Steel Pricing

Pricing Considerations

While understanding the annealed hardness is crucial, considering the overall cost of A2 steel is equally important. Prices may vary based on factors such as size, quantity, and supplier, but the investment in quality A2 steel pays off in its ease of machinability and subsequent hardening processes.

Sourcing Success: Finding the Right A2 Steel Supplier

Smart Sourcing Strategies

For those seeking annealed A2 steel, finding a reliable supplier is key. Look for suppliers with a proven track record, certifications, and positive customer feedback. Establishing a relationship with a trustworthy supplier ensures consistent access to quality A2 steel in its annealed state.

Conclusion: Annealed A2 Steel – -A2 Steel in its Annealed State

In conclusion, exploring A2 steel in its annealed state unveils a canvas of possibilities. Understanding its standard, composition, applications, and annealed hardness sets the stage for crafting precision tools and components with ease.