A2 Steel for Knives-why it is a preferred material for knife blades

A2 steel is an air-hardening tool steel known for its exceptional toughness and wear resistance. It contains carbon, chromium, molybdenum, vanadium and other alloying elements to form a strong alloy with excellent edge retention and corrosion resistance. The controlled composition of A2 steel helps it achieve high hardness levels while maintaining toughness.

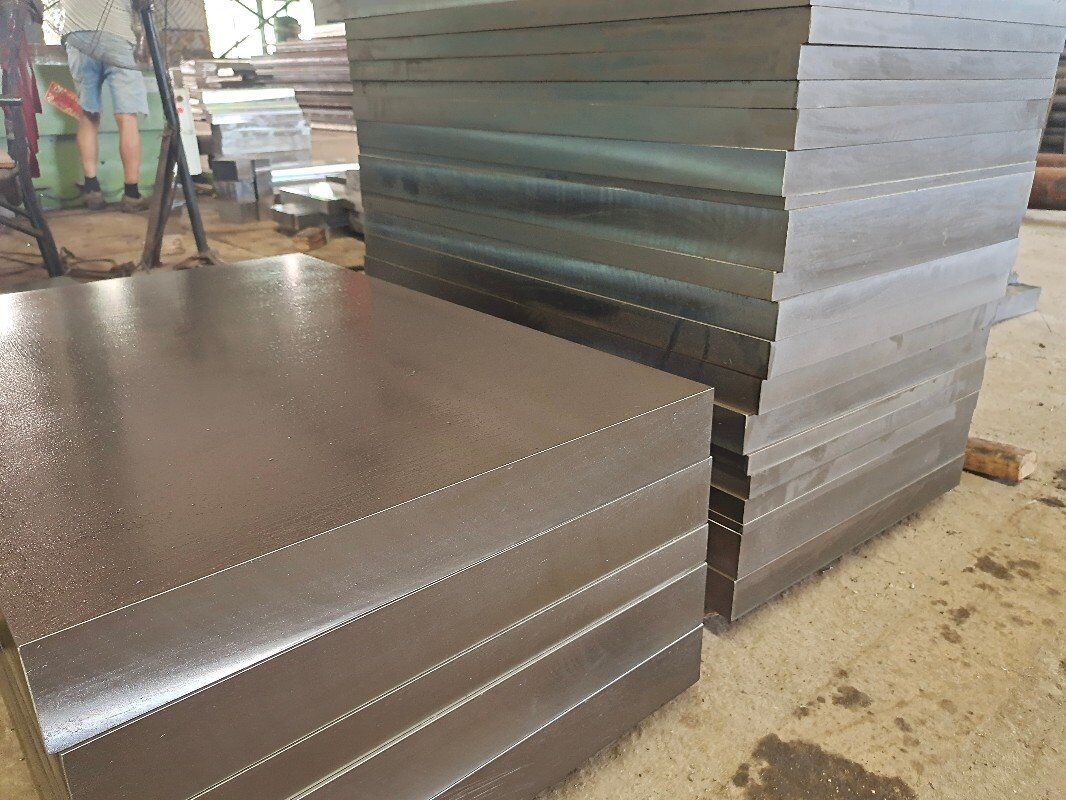

Manufacturing process: Excellent forging

Making knives from A2 steel requires a meticulous manufacturing process. The steel is forged under controlled conditions, ensuring a uniform and fine-grained structure. This process not only enhances the mechanical properties of the steel, but also allows for precise shaping, resulting in the knife’s superior cutting performance.

Heat treatment magic: achieving optimal hardness

A2 steel’s unique heat treatment response is a key factor in its performance. Properly heat treated A2 steel provides an ideal balance of hardness and toughness, making it suitable for a variety of cutting tasks. The heat treatment process includes austenitizing, quenching and tempering, with each step carefully executed to achieve optimal blade performance.

Blade sharpness: A2 steel cutting edge

One of the outstanding features of A2 steel is its ability to obtain and maintain sharp edges. The fine-grain structure and alloying elements work together to resist edge deformation, ensuring that knives made from A2 steel remain sharp after long-term use. This feature makes A2 steel knives a favorite among chefs who demand precision from their knives.

Corrosion Resistance: Anti-rust barrier for A2 steel

Although A2 steel is not classified as stainless steel, it has commendable corrosion resistance. The chromium content, although moderate, forms a protective oxide layer that reduces the risk of rust, making A2 steel knives suitable for use in a variety of environments, including kitchens where they are regularly exposed to moisture.

Easy maintenance: keep your tools in top condition

A2 steel knives are not only known for their cutting capabilities, but also for their ease of maintenance. Regular honing and proper cleaning are usually enough to keep your blades in top condition. Additionally, the steel’s resistance to chipping and rolling reduces the frequency of sharpening, increasing overall user convenience.

Diversity of applications: from kitchen to outdoors

The versatility of A2 steel isn’t limited to kitchen knives. Its combination of hardness and toughness makes it the material of choice for outdoor and survival knives. Whether cutting tough materials in the wilderness or carefully preparing ingredients in the kitchen, A2 steel knives demonstrate their adaptability in a variety of cutting tasks.

Choosing an A2 Steel Knife: Factors to Consider

When choosing an A2 steel knife, you should consider factors such as blade design, handle material, and intended use. Different tool manufacturers may have unique methods of heat treatment and blade geometry that affect the overall performance of the tool. Users must understand their specific needs and preferences to make informed choices.