A2 Steel Heat Treat: Mastering Strength and Durability

A2 Steel Heat Treat: Mastering Strength and Durability

Introduction to A2 Steel

A2 steel, known for its exceptional toughness and wear resistance, stands as a cornerstone in the arsenal of steels available today. Its composition, rich in chromium and vanadium, imbues it with properties that make it ideal for a wide range of applications, from toolmaking to industrial machinery components.

Why Choose A2 Steel?

When it comes to selecting the right steel for your needs, A2 steel shines bright. Its unique blend of alloying elements ensures:

- High hardness retention

- Excellent machinability

- Superior dimensional stability

These qualities make A2 steel a preferred choice among discerning professionals who prioritize reliability and performance.

A2 Steel Heat Treatment Process

The heat treatment of A2 steel is critical to harnessing its full potential. Here’s a breakdown of the process:

- Annealing: Begin by heating the A2 steel to a precise temperature and holding it there to achieve a uniform structure. This step reduces internal stresses and prepares the steel for further treatment.

- Hardening: Rapidly quench the steel in oil or air after heating it to a specified temperature, typically between 1700°F to 1850°F (925°C to 1010°C). This process ensures the steel achieves maximum hardness.

- Tempering: This crucial step involves reheating the hardened steel to a lower temperature (around 400°F to 1000°F or 200°C to 540°C) to enhance toughness and reduce brittleness. The exact temperature depends on the desired balance between hardness and toughness required for the application.

Advantages of A2 Steel Heat Treat

By meticulously following the heat treatment process, A2 steel offers:

- Exceptional wear resistance: Ensures prolonged tool life and reduced maintenance costs.

- High compressive strength: Withstands heavy loads and high-stress applications.

- Good machinability: Facilitates ease of shaping and finishing operations.

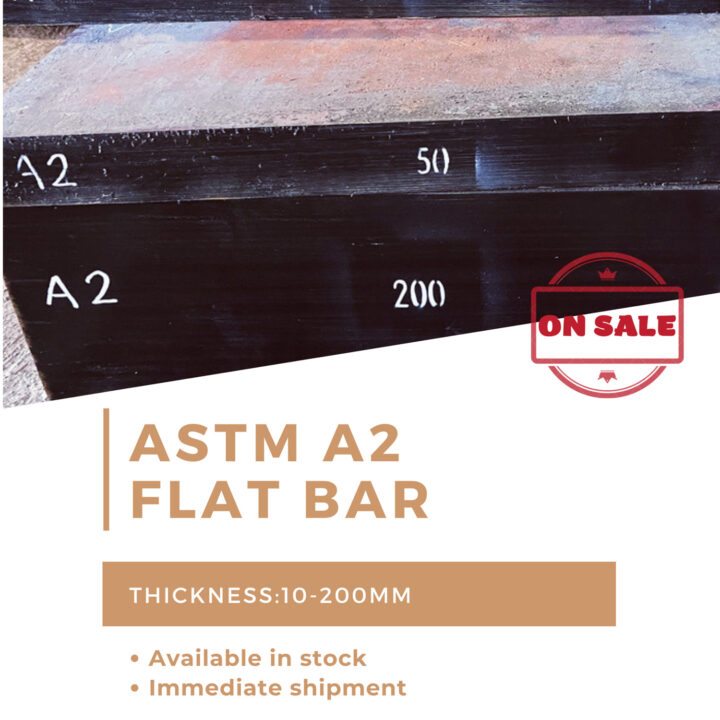

OTAI’s Commitment to Quality and Service

At OTAI, we take pride in offering top-notch A2 steel products tailored to your exact specifications. Here’s why you should partner with us:

- Comprehensive Inventory: Our warehouses are stocked year-round with A2 steel in all sizes, ready for immediate customization to meet your specific needs.

- Custom Packaging Solutions: Whether you require cable tie packaging, wooden box packaging, or rust-proof packaging, we’ve got you covered.

- Proven Track Record: We’ve supplied significant quantities of A2 steel to some of the world’s leading companies, meeting their stringent technical requirements with precision and reliability.

Customer Success Stories

Let’s dive into real-world examples where OTAI’s A2 steel made a difference:

- Case Study 1: Automotive Tooling

A leading automotive manufacturer required durable cutting tools for their production line. OTAI’s A2 steel, combined with expert heat treatment, delivered tools that exceeded performance expectations, resulting in enhanced productivity and cost savings. - Case Study 2: Aerospace Components

A major aerospace contractor needed high-strength components resistant to wear and fatigue. By choosing OTAI’s A2 steel, they achieved components that met stringent safety standards while optimizing operational efficiency.

Conclusion

In conclusion, A2 steel’s heat treat process unlocks its full potential, offering unparalleled strength, durability, and machinability. When you partner with OTAI, you not only gain access to superior quality A2 steel but also benefit from our commitment to excellence and customer satisfaction. Whether you’re in automotive manufacturing, aerospace, or any industry that demands reliable performance, A2 steel from OTAI is your trusted solution.

For more information on how A2 steel can elevate your projects, contact us today. Discover the difference quality steel can make in your applications with OTAI’s expertise and dedication to your success.