A2 Steel vs O1 Steel-Choosing Your Steel Companion

In the realm of tool steels, the choice between A2 and O1 steel can be pivotal, each offering distinct characteristics that cater to specific applications. This comprehensive guide aims to decode the differences between A2 and O1 steel, covering standards, chemical composition, applications, sizes, prices, and more.

Decoding Standards: A2 and O1 in Context

A2 Steel Standard: A2 steel adheres to specific standards, often denoted by ASTM or AISI codes. Understanding these standards is crucial for ensuring the material meets desired specifications. ASTM A681 is a commonly referenced standard for A2 steel.

O1 Steel Standard: O1 steel, on the other hand, is often associated with the ASTM A681 standard as well. Recognizing and adhering to these standards ensures consistency in material properties and quality.

Chemical Composition: The Alloy Alchemy

A2 Steel Composition: A2 steel boasts a composition that includes chromium, molybdenum, vanadium, carbon, and manganese. This blend contributes to its exceptional hardness, wear resistance, and toughness.

O1 Steel Composition: O1 steel features a composition rich in manganese, chromium, carbon, and tungsten. This unique mix enhances its machinability, wear resistance, and ability to be hardened.

Applications: A2 and O1 in Action

A2 Steel Applications: A2 steel finds its niche in applications demanding a combination of high hardness and toughness. Common uses include blanking dies, cutting tools, and intricate components where wear resistance is crucial.

O1 Steel Applications: O1 steel, with its emphasis on machinability and wear resistance, is often favored in applications such as forming dies, punches, and woodworking tools. Its ability to be hardened easily makes it suitable for various cutting applications.

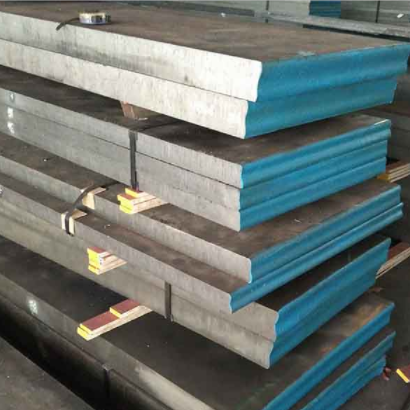

Size Matters: Dimensions and Forms

A2 Steel Sizes: A2 steel is available in various sizes, from sheets and plates to bars and custom shapes. Its sizing flexibility caters to diverse manufacturing needs, ensuring versatility in tool and component production.

O1 Steel Sizes: Similarly, O1 steel comes in different forms, adapting to the requirements of specific applications. Availability in various sizes ensures that manufacturers can choose the right dimensions for their tools and components.

Price Dynamics: Balancing Cost and Quality

A2 Steel Prices: The cost of A2 steel is influenced by factors such as size, form, and supplier reputation. While it provides an excellent balance of hardness and toughness, understanding the price dynamics ensures a cost-effective choice.

O1 Steel Prices: O1 steel’s cost is also determined by factors like size, form, and supplier reputation. Balancing quality with budget considerations is essential to making a judicious purchasing decision.

Sourcing Considerations: Finding the Right Supplier

Sourcing A2 Steel: Finding a reliable supplier for A2 steel involves thorough research. Checking certifications, customer reviews, and assessing the supplier’s reputation can guide you to a source that aligns with your quality expectations.

Sourcing O1 Steel: Similarly, when sourcing O1 steel, considerations like certifications, reputation, and customer feedback play a pivotal role. A trustworthy supplier ensures the material meets your specifications consistently.

Conclusion: A2 Steel vs O1 Steel-Choosing Your Steel Companion

In conclusion, the choice between A2 and O1 steel hinges on the specific needs of your application. A2 excels in applications requiring a balance of hardness and toughness, while O1 is favored for its machinability and wear resistance. Understanding these differences ensures you make an informed decision that aligns with your tooling requirements.