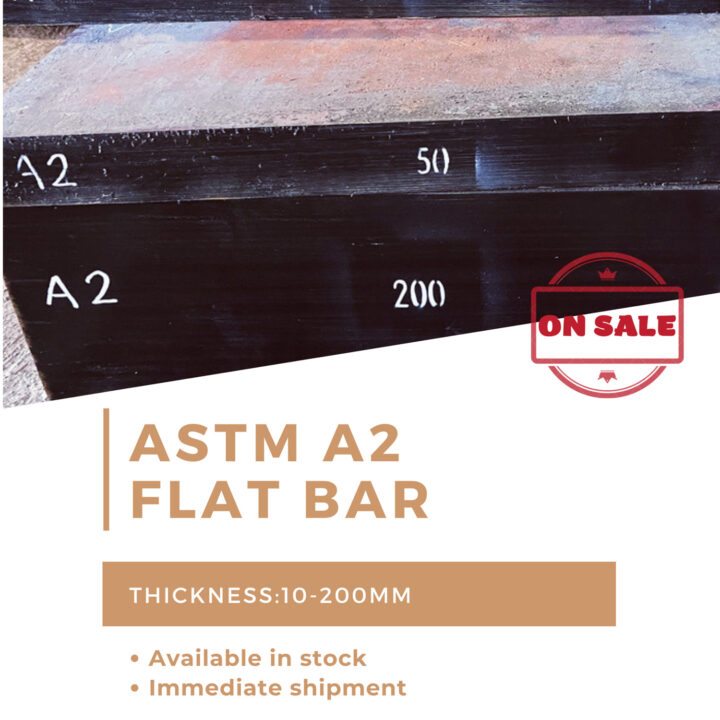

A2 tool steel is an air-hardening, cold work steel. A2 is a 5% Chromium steel which provides high hardness after heat treatment with good dimensional stability. It is heat treatable and will offer a hardness in the range of 57-62 HRC.

Otai can supply the a2 steel, we have a customer who is a knife stockist in Russia, they produce the different knives made of steel, but the knife made of a2 steel is most appreciated, he purchased the a2 steel from our company every year. We paid a visit with the customer in September, we knew most people bought the knife for wood carving, food preparation, cleaning fish, and possibly wilderness survival.

Characteristics of A2 tool steel

1good machinability,

2high compressive strength,

3high dimensional stability after hardening and tempering.

4Good hardenability, very good non-deforming properties, deep hardening,

5Good wear resistance, AISI A2 tool steel takes a place between AISI O1 and AISI D2, offering an excellent combination of good wear resistance and toughness.

Applications

Typical Applications for A2 tool steels materials: Blanking dies, block and ring gauges, coining, cold forming, cold trimming and forming dies, cold shears, rolls, knurls and knurling tools, machine parts, mandrels, punches and punch plates, reamers, shear, and slitter blades, stamping dies and threading tapes.

Company History

Otai Steel supplies a wide range of carbon, alloy, and stainless steel products, including high-speed tool steel, cold works tool steel, hot works tools steel, plastic mold steel, engineering steel, and machine structural steel, etc. After almost 20 years of development and growth, Otai Steel becomes one comprehensive special steel factory, stockist, and exporter. Combined with the experienced exporting team and professional technical knowledge, Otai Steel offers both technical advice and support, as well as global professional steel solution and service.