Advancements in 30CrNiMo8 Alloy

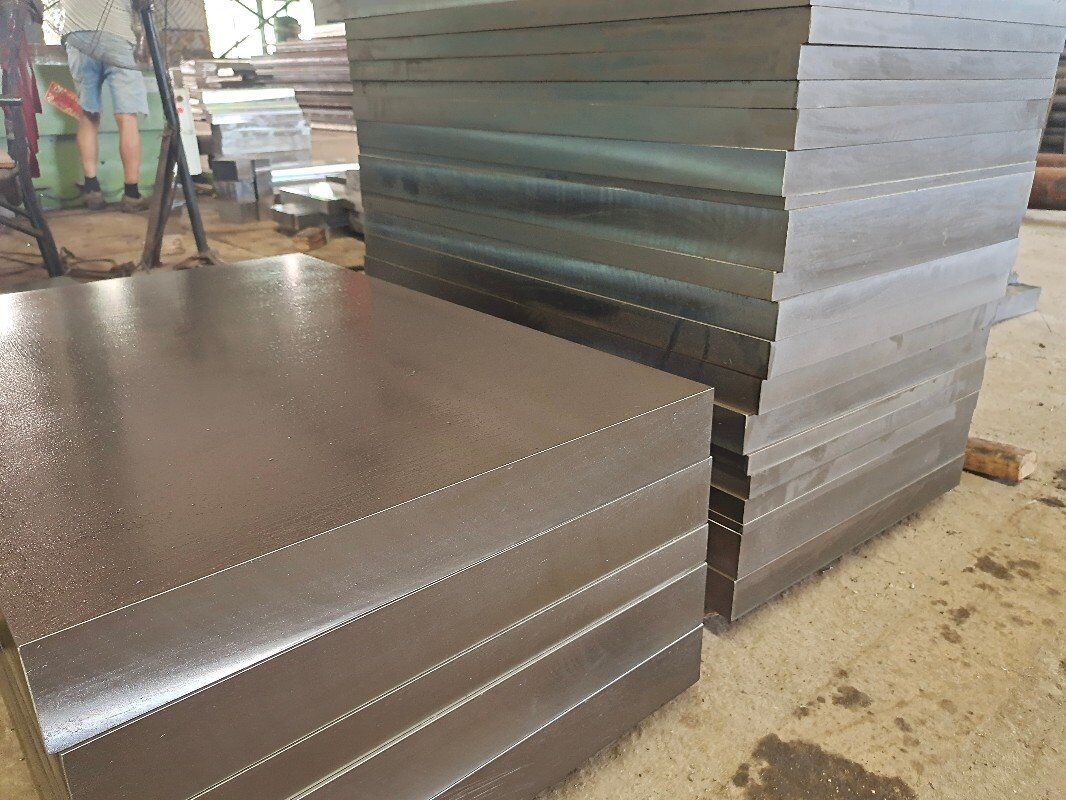

In the ever-evolving landscape of metallurgy, where progress is marked by innovation, 30CrNiMo8 alloy stands at the forefront of advancements. This steel alloy, known for its exceptional strength and versatility, has witnessed significant developments that propel it into new frontiers of applications. Let’s delve into the exciting world of advancements in 30CrNiMo8 alloy, exploring how it continues to redefine possibilities in various industries.

The Core Chemistry: A Synthesis of Strength and Resilience

At the heart of 30CrNiMo8 alloy’s advancements lies its unique chemical composition. The synergy of chromium, nickel, and molybdenum creates a steel alloy that not only withstands intense mechanical stresses but also exhibits remarkable resistance to corrosion. This foundational chemistry sets the stage for the alloy’s continuous evolution.

Heat Treatment Innovations: Tailoring Properties for Precision

Advancements in heat treatment techniques have played a pivotal role in refining the properties of 30CrNiMo8 alloy. Precise temperature control and quenching processes have been developed to enhance the alloy’s hardness, toughness, and fatigue resistance. These innovations ensure that the alloy can meet the stringent demands of modern applications, from machinery components to aerospace engineering.

Nanostructuring Marvels: Redefining Microscopic Landscapes

A leap into the microscopic realm reveals another facet of 30CrNiMo8 alloy’s advancements – nanostructuring. Through meticulous engineering at the nanoscale, the alloy’s grain structure is optimized, resulting in improved mechanical properties. This nanostructuring marvel enhances the alloy’s performance in critical applications, contributing to its reputation as a high-performance material.

Digital Twins in Alloy Design: Precision Engineering in the Virtual World

The digital era has ushered in a new wave of innovation, and 30CrNiMo8 alloy has embraced this trend with the integration of digital twins in alloy design. Virtual simulations and modeling techniques allow engineers to predict and optimize the alloy’s behavior under different conditions. This digital approach not only accelerates the development process but also ensures that the alloy is tailored for specific applications with unparalleled precision.

Corrosion-Resistant Coatings: Guarding Against Environmental Challenges

Advancements in corrosion-resistant coatings have extended the lifespan of 30CrNiMo8 alloy in harsh environments. Protective layers, ranging from polymer coatings to advanced metal alloys, act as shields against corrosive agents. This breakthrough ensures that the alloy maintains its structural integrity even in aggressive industrial settings, expanding its applications in chemical plants, marine environments, and more.

Industry-Specific Alloy Variants: Tailoring to Diverse Needs

Recognizing the diverse requirements across industries, researchers have developed industry-specific variants of 30CrNiMo8 alloy. Tailoring the alloy to address unique challenges in automotive, aerospace, and energy sectors ensures that it remains a versatile solution across a spectrum of applications. These specialized variants showcase the adaptability of 30CrNiMo8 alloy in meeting the evolving needs of various industries.

Smart Manufacturing Integration: Enhancing Production Efficiency

In the era of Industry 4.0, smart manufacturing practices have found their way into the production of 30CrNiMo8 alloy. Sensors, data analytics, and automation contribute to enhanced quality control and production efficiency. This integration not only ensures consistency in alloy properties but also facilitates the rapid scaling of production to meet growing demands.

Environmental Sustainability: A Green Focus on Alloy Production

Advancements in alloy production methods are not only about performance but also about environmental sustainability. The industry is actively exploring greener alternatives, such as energy-efficient processes and recycling initiatives, to reduce the environmental footprint of 30CrNiMo8 alloy production. This commitment to sustainability aligns with global efforts towards responsible and eco-friendly metallurgy.

Conclusion: Paving the Way for a New Era in Metallurgy

In conclusion, the advancements in 30CrNiMo8 alloy epitomize the relentless pursuit of excellence in metallurgy. From precise heat treatments to digital engineering innovations, the alloy continues to redefine possibilities. As it ventures into new applications and industries, 30CrNiMo8 alloy stands as a testament to the ever-evolving nature of materials science, paving the way for a new era in metallurgical advancements.