Welding Guidelines for 4140 Steel: Ensuring Precision, High Performance, and Quality Standards

Welding Guidelines for 4140 Steel: Ensuring Precision, High Performance, and Quality Standards

In alloy steels, 4140 sets the standard for strength and durability. Its chromium and molybdenum blend makes it ideal for high-performance uses. Welding 4140 is not merely a technique but a sophisticated science that OTAI has mastered.

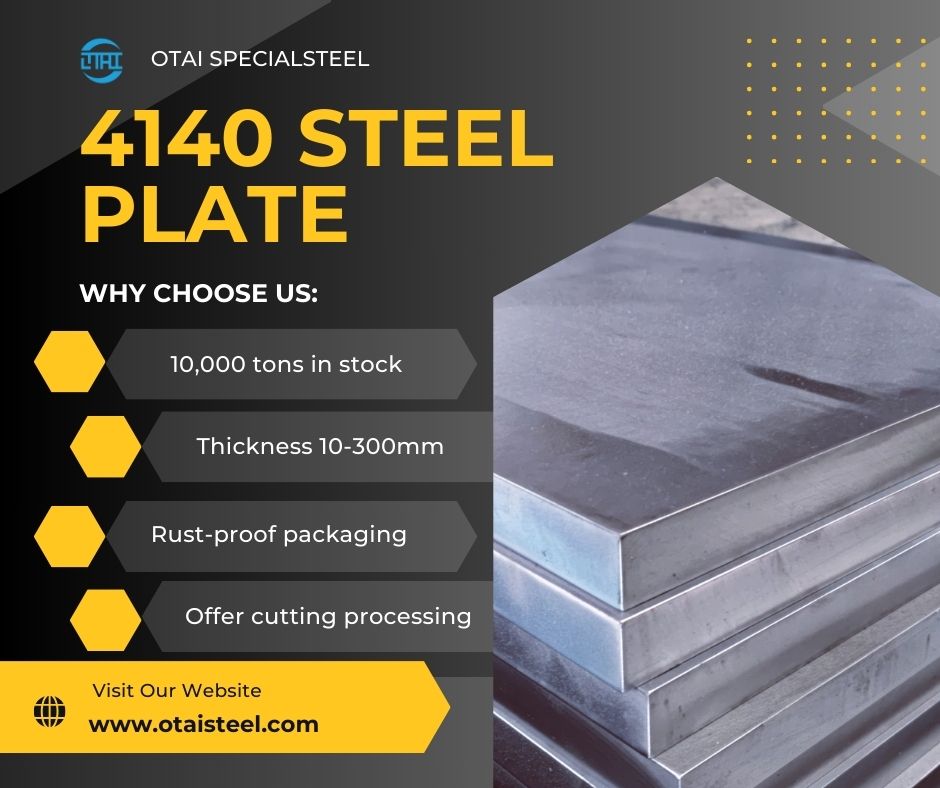

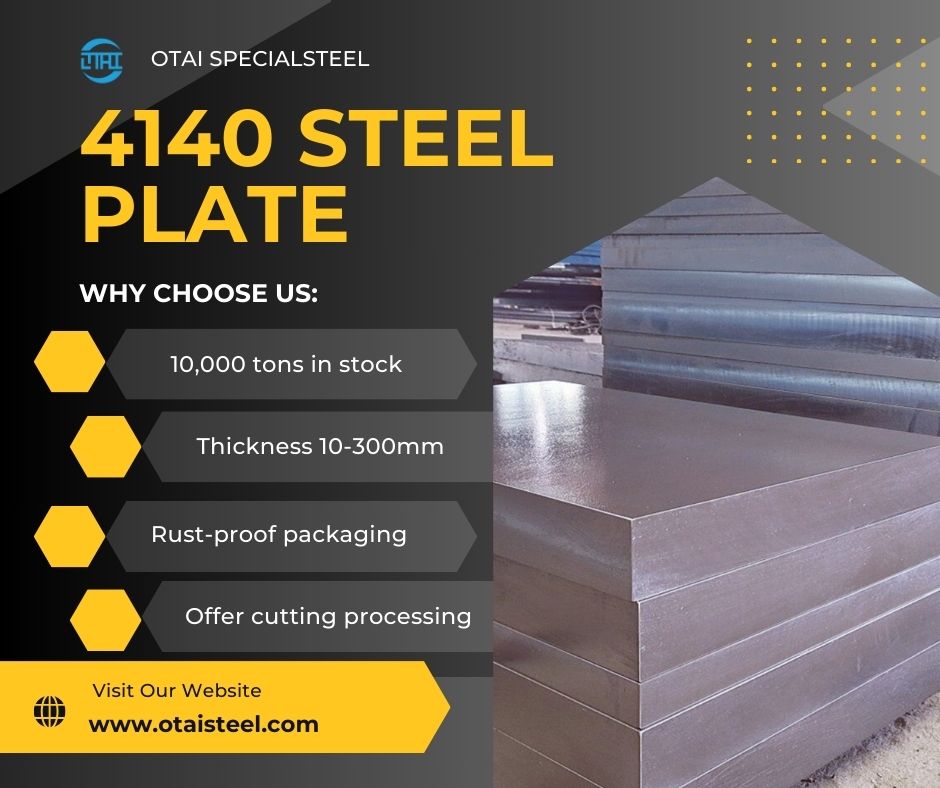

OTAI’s Commitment to Quality: Stock and Custom Solutions

OTAI demonstrates its dedication through a vast inventory of 4140 steel in various thicknesses, ready for immediate delivery. We provide more than just steel; we offer tailored solutions, including precise cutting and customized packaging to meet your project’s needs.

Understanding 4140 Steel’s Properties

4140 steel’s high carbon content enhances hardness but poses challenges for welding. Our specialists excel in welding this material, ensuring each weld reflects our expertise.

Designing the Ultimate Welding Process for 4140 Steel

OTAI’s welding process for 4140 includes preheating to prevent cold cracking. We use the latest industry insights to choose compatible welding consumables, achieving optimal results.

Advanced Welding Techniques

Our approach blends innovation with tradition, employing Gas Tungsten Arc Welding (GTAW) for precision and Shielded Metal Arc Welding (SMAW) for versatility. These methods are selected to ensure strong and reliable welds.

Addressing Welding Challenges

Welding 4140 involves challenges like distortion and hard zones. Our skilled team uses advanced equipment and strategic methods to address these issues, ensuring high-quality results.

Post-Weld Heat Treatment: Ensuring Excellence

Our post-weld heat treatment addresses residual stresses, enhancing the durability and integrity of the welds.

Quality Assurance: OTAI’s High Standard

We maintain rigorous quality checks and tests to ensure each weld meets our high standards, reflecting our commitment to excellence.

Safety First: A Core Principle

Safety is fundamental at OTAI. We adhere to strict safety protocols to ensure a secure working environment for our team and maintain process integrity.

OTAI: A Trusted Global Partner

Our reputation for quality has been solidified through partnerships with global enterprises, consistently exceeding technical expectations.

Versatility and Consistency

4140 steel’s diverse applications require a versatile welding approach. OTAI guarantees exceptional quality across various projects, from aerospace to heavy machinery.

Stress Relieving: Ensuring Reliability

Our welding process includes stress relieving, essential for the long-term reliability of the welds. This attention to detail sets OTAI apart in 4140 steel welding.

Summary: Welding Guidelines for 4140 Steel

OTAI’s legacy in 4140 Steel Welding Procedure is marked by excellence. Our comprehensive approach, from inventory to post-weld treatments, delivers not just a product but a commitment to quality and reliability.

How to Quench 4140 Steel for Maximum Alloy Strength

How to Quench 4140 Steel for Maximum Alloy Strength Discovering the Exceptional Properties of Forged 4140 Steel

Discovering the Exceptional Properties of Forged 4140 Steel Improving AISI 4140 Steel Performance Through Composition Adjustments

Improving AISI 4140 Steel Performance Through Composition Adjustments Improving the Utility of AISI 4140 Steel by Modifying Its Chemical Composition

Improving the Utility of AISI 4140 Steel by Modifying Its Chemical Composition 4140 Steel Processing: Transforming from Furnace to Finished Component

4140 Steel Processing: Transforming from Furnace to Finished Component From Raw 4140 Steel to Refined Cuts: A Processing Overview

From Raw 4140 Steel to Refined Cuts: A Processing Overview Harnessing the Full Capabilities of Precision Ground 4140 Steel with OTAI

Harnessing the Full Capabilities of Precision Ground 4140 Steel with OTAI 4140 Precision Ground Flat Stock: Ideal for Precision Engineering Needs

4140 Precision Ground Flat Stock: Ideal for Precision Engineering Needs OTAI’s 4140 Precision Ground Bars: The Epitome of Precision Engineering

OTAI’s 4140 Precision Ground Bars: The Epitome of Precision Engineering 4140 Precision Ground Flats Stock: OTAI is your ideal partner

4140 Precision Ground Flats Stock: OTAI is your ideal partner The Role of 4140 Ground Flat Bars in Industrial Fabrication

The Role of 4140 Ground Flat Bars in Industrial Fabrication