Otai S50C plate shipment to Asia

4140 hot rolled plate producing

4140 steel plate

4140 plate stocking

4140 hot rolled plate

4140 hot rolled plate stocking

Tool steel making 1.2379

1.2379 Tool Steel | D2 | SKD11 | Cr12Mo1V1 Alloy Steel

20Cr2Ni4 Alloy Steel Plate

1)20Cr2Ni4 steel is a high-quality Cold work tool steel, It belongs to the high-quality high carbon alloy tool steel. Oil Quenched & Tempered Hardness is 423 HB.

2) 20Cr2Ni4 Chemical composition

| C(%) | 0.17~0.23 | Si(%) | 0.17~0.37 | Mn(%) | 0.30~0.60 | Cr(%) | 1.25~1.65 |

| Ni(%) | 3.25~3.65 |

3) 20Cr2Ni4 Mechanical Properties

The mechanical properties of 20Cr2Ni4 tool steels are outlined in the following table.

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV/Ku (J) |

Elongation A (%) |

Reduction in cross-section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HB) |

|---|---|---|---|---|---|---|

| 155 (≥) | 945 (≥) | 14 | 32 | 31 | Solution and Aging, Annealing, Ausaging, Q+T, etc | 423 |

20MnCr5 Carburized steel

Steel grade 20MnCr5 is a structural alloy steel for surface hardening produced to the requirements of ISO 683-3/ EN 10084.

2. 20MnCr5 Classification: Structural alloy steel.

3. 20MnCr5 Products: Semi-finished products, rods, wide strip, plates and forgings.

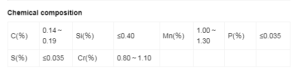

4. 20MnCr5 Chemical composition

| C(%) | 0.17~0.22 | Si(%) | ≤0.40 | Mn(%) | 1.10~1.40 | P(%) | ≤0.035 |

| S(%) | ≤0.035 | Cr(%) | 1.00~1.30 |

5. 20MnCr5 Heat treatment Related

Slowly heated to 790-810 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Different annealing ways will get different hardness.The 20MnCr5|1.7147 Carburizing steel will get Hardness MAX 248 HB (Brinell hardness).

Heated slowly to 788°C, Then put in salt-bath furnace keep 1191 ℃ to 1204 ℃。quenching by oil get 60 to 66 HRc hardness. High temperature tempering: 650-700℃,cool in air, get hardness 22 to 30HRC. Low temperature tempering: 150-200 ℃, Cool in ari, get 61-66HRC hardness.

DIN 16MnCr5|1.7131 steel can hot worked at 205 to 538°C, 16MnCr5|1.7131 gearing steel can be cold worked using conventional techniques in the annealed or normalized conditions.

6. Mechanical Properties Of 20MnCr5|1.7147 gearing steel

The mechanical properties of annealed DIN 20MnCr5|1.7131 gearing steel (typical for steel) are outlined in the table below:

| Tensile | Yield | Bulk modulus | Shear modulus | Poisson’s ratio | Thermal conductivity | |

| MPa | Mpa | Gpa | Gpa | W/mK | ||

| 520 | 415 Min | 140 | 80 | 0.27-0.30 | 46.6 |

7.Applications of 20MnCr5|1.7147 Carburizing steel

DIN 20MnCr5|1.7147 gearing steel steel is widely used for a variety of applications in the used to the gearings in rotating machinery.

Typical applications such as: valve bodies, pumps and fittings, the high load of wheel, bolts, double-headed bolts, gears, internal combustion engine. Electric locomotives, machine tools, tractors, steel rolling equipment, boring machine, railway vehicle, and mining machinery transmission shaft on the steel ball, roller and shaft sleeve, etc.

1.6523 case hardening steel

1.6523 Nickel–Chrome–Moly Carburising Steel

1.6523 has a high case toughness and above average core toughness due to the nickel content.

2. 1.6523 Steel Specification and Relevant Standards

| Country | USA | DIN | BS | BS | Japan |

| Standard | ASTM A29 | DIN 1654 | EN 10084 | BS 970 | JIS G4103 |

| Grades | 8620 | 1.6523/ 21NiCrMo2 |

1.6523/ 20NiCrMo2-2 |

805M20 | SNCM220 |

3. 1.6523 Steels & Equilvalents Chemical Composition

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A29 | 8620 | 0.18-0.23 | 0.7-0.9 | 0.035 | 0.040 | 0.15-0.35 | 0.4-0.7 | 0.4-0.6 | 0.15-0.25 |

| DIN 1654 | 1.6523/ 21NiCrMo2 |

0.17-0.23 | 0.65-0.95 | 0.035 | 0.035 | ≦0.40 | 0.4-0.7 | 0.4-0.7 | 0.15-0.25 |

| EN 10084 | 1.6523/ 20NiCrMo2-2 |

0.17-0.23 | 0.65-0.95 | 0.025 | 0.035 | ≦0.40 | 0.4-0.7 | 0.35-0.70 | 0.15-0.25 |

| JIS G4103 | SNCM220 | 0.17-0.23 | 0.6-0.9 | 0.030 | 0.030 | 0.15-0.35 | 0.4-0.7 | 0.4-0.65 | 0.15-0.3 |

| BS 970 | 805M20 | 0.17-0.23 | 0.6-0.95 | 0.040 | 0.050 | 0.1-0.4 | 0.35-0.75 | 0.35-0.65 | 0.15-0.25 |

4. 1.6523 Steel Mechanical Properties

Density (lb / cu. in.) 0.283

Specific Gravity 7.8

Specific Heat (Btu/lb/Deg F – [32-212 Deg F]) 0.1

Melting Point (Deg F) 2600

Thermal Conductivity 26

Mean Coeff Thermal Expansion 6.6

Modulus of Elasticity Tension 31

| Properties | Metric | Imperial |

| Tensile strength | 530 MPa | 76900 psi |

| Yield strength | 385 MPa | 55800 psi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Izod Impact | 115 J | 84.8 ft.lb |

| Hardness, Brinell | 149 | 149 |

| Hardness, Knoop (converted from Brinell hardness) | 169 | 169 |

| Hardness, Rockwell B (converted from Brinell hardness) | 80 | 80 |

| Hardness, Vickers (converted from Brinell hardness) | 155 | 155 |

| Machinability (hot rolled and cold drawn, based on 100 machinability for AISI 1212 steel) | 65 | 65 |

5. Forging of Material 1.6523 Steel

1.6523 alloy steel is forged at a start temperature of around 2250ºF (1230ºC) down to approximately 1700ºF(925ºC.) prior to the hardening heat treatment or carburizing. The alloy is air cooled after forging.

6. 1.6523 Applications

Additionally, it is the most widely used carburizing alloy steel. Typical uses include: gears, cranks, shafting, axles, bushings, heavy duty pins, bolting, springs, hand tools,and many other machinery parts.

| Country | USA | DIN | BS | Japan |

| Standard | ASTM A29 | EN 10250/EN10083 | BS 970 | JIS G4105 |

| Grades | 4130 | 25CrMo4/1.7218 | 708A25/708M25 | SCM430 |

| Standard | Grade | C | Mn | P | S | Si | Cr | Mo |

| ASTM A29 | 4130 | 0.28-0.33 | 0.40-0.60 | 0.035 | 0.040 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| EN10250 /EN10083 |

25CrMo4/ 1.7218 |

0.22-0.29 | 0.60-0.90 | 0.025 | 0.035 | ≦0.40 | 0.90-1.2 | 0.15-0.30 |

| JIS G4105 | SCM430/ SCM2 |

0.28-0.33 | 0.60-0.85 | 0.030 | 0.030 | 0.15-0.35 | 0.90-1.2 | 0.15-0.30 |

4.DIN 25CrMo4 /AISI Alloy 4130 Steel Mechanical Properties

25CrMo4 / 4130 Physical Properties

DIN 25CrMo4 /AISI 4130 Steel Mechanical Properties

| Properties | Metric |

| Tensile strength, ultimate | 560 MPa |

| Tensile strength, yield | 460 MPa |

| Modulus of elasticity | 190-210 GPa |

| Bulk modulus (Typical for steel) | 140 GPa |

| Shear modulus (Typical for steel) | 80 GPa |

| Poissons ratio | 0.27-0.30 |

| Elongation at break (in 50 mm) | 21.50% |

| Reduction of area | 59.6 |

| Hardness, Brinell | 217 |

| Hardness, Knoop (Converted from Brinell hardness) | 240 |

| Hardness, Rockwell B (Converted from Brinell hardness) | 95 |

| Hardness, Rockwell C (Converted from Brinell hardness, value below normal HRC range, for comparison purposes only.) | 17 |

| Hardness, Vickers (Converted from Brinell hardness) | 228 |

| Machinability (Annealed and cold drawn. Based on 100% machinability for AISI 1212 steel.) | 70 |

Thermal Properties

| Properties | Metric |

| Thermal conductivity (100°C) | 42.7 W/mK |

5. DIN 25CrMo4 /AISI 4130 Steel Application

This low alloy 4130 steel is widely used in many applications, and some typical application areas are as follows:

https://otaialloysteel.com/3-steel-grades-suitable-for-making-gear/

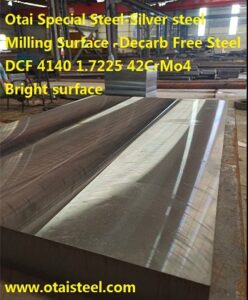

4140 Pre-Hard STEEL PLATE

Otai has great advantage on 4140 steel plate:

4140 Chemical Composition

| AISI 4140 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.43 | 0.75-1.00 | 0.15-0.35 | 0.035 max | 0.040 | 0.80-1.10 | 0.15-0.25 |

4140 Relevant Specifications and Equivalents

| ASTM A29 | Material No. | DIN | BS EN 10083 | JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | AFNOR |

| 4140 | 1.7225 | 38HM | 42CrMo4 | SCM440 | 708M40 | EN19A | 4140 | 42CD4 |

4140 steel can be used for a wide variety of applications where better wear resistance and toughness is needed over normal carbon steels.

Common uses of 4140 steel plate:

tooling, machine plates, gears, shafts, sprockets, special machine parts, molds, metal stamping, tool & die, shredders, couplings, reamer bodies, screws, flywheel components, axles, shafts, bolts, sprockets, piston rods and rams. diamond cutter Construction

https://otaialloysteel.com/16mncr5/

60Si2MnA Alloy Steel Spring Steel

Otai Specials steel 60Si2MnA Alloy Steel Round Bar 60Si2Mn Spring Steel

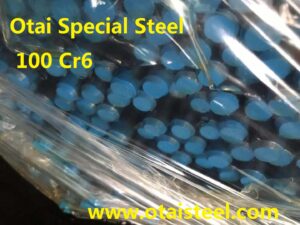

Bearing Steel 100Cr6-Through-hardening Bearing Steel

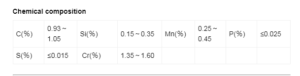

Chemical composition

Through-hardening steel contains typically 1% carbon and alloying elements for hardenability, exhibiting very high strength but low ductility. Used with martensitic or bainitic hardening.

100Cr6 is equivalent to AISI 52100, GB GCr15.

Heat Treatment

In order to harden steel, the iron matrix must contain a certain amount of carbon.

The higher carbon content in the steel the higher achievable hardness. In through-hardening steel, there is a relatively high level of carbon added to the steel. When the component is heat treated, it becomes hard all the way through from the surface to the core, hence the term “through-hardened”. Through-hardened steel components are relatively brittle and can fracture under impact or shock loads.

Applications

for through-hardening bearing steel are typically roller bearing components but also components that require high fatigue strength such as diesel injection components.

The hardness levels these steel reach also makes them excellent in wear applications or cutting/slitting/grinding applications.

When also combined with a stabilizing heat treatment they give a dimensional stability needed in many tool steel applications.

No comments by Cathy Liu

Otai Special Steel is stable supplier for Voestalpine & Thyssenkrupp, with ISO9001 certified. We Supply Top Quality Tool Steel and Alloy Steel.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

WhatsApp: +8676923190193

Email (English): jack@otaisteel.com

Email (Español): jack@otaisteel.com

Address: 1F, Building B, Sanfang Industrial Area, Xiansha, Gaobu Town, Dongguan City, Guangdong Province, P.R. China