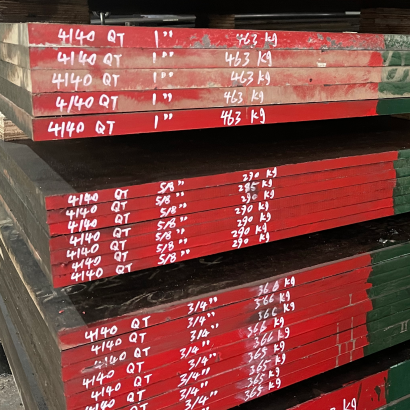

4140 Alloy Structural Steel

ASTM 4140 Steel is a Alloy Structural Steel. AISI 4140 is a chromium molybdenum alloy steel, widely used in Oil and Gas industry and Large Machinery Strutural. Also used for components like axles, shafts, bolts, gears and other applications. 4140 Steel Plate China Supplier and factory Otai Special Steel Supply ASTM 4140 steel in Round bar, Plate, Flat bar, Square, Forging Ring and others any shape. And provide cutting, sawing, milled, machining processing.

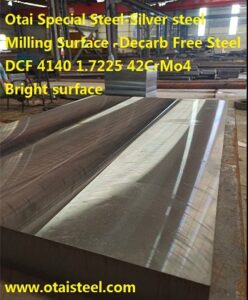

4140 Steel sheet equivalent standards:

| ASTM | DIN | BS | JIS | GB |

| 4140 | 1.7225/42CrMo4 | 42CrMo4 | SCM440 | 42CrMo |

4140 steel Mechanical Properties:

Tensile strength:655 MPa

Yield strength:415 MPa

Elongation at break (in 50 mm):25.70%

Poisson’s ratio:0.27-0.30