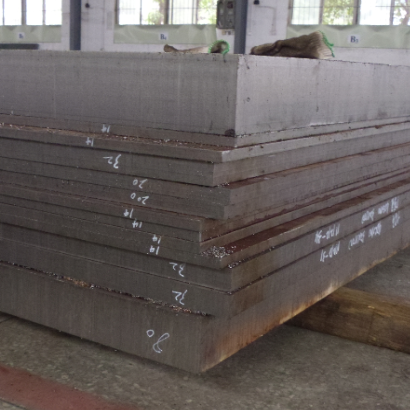

1.6580 steel is alloy structural steel with medium hardenability designed for heavy duty components, characterized by high elasticity. When softened, the hardness could reaches 248 HRB. It is also characterized by its resistance to variable loads and impacts. 1.6580 material is not suitable for welding and ultimately requires additional preheating.

1.6580 Steel equivalent standards:

| EN | EN | AISI/ASTM | PN | ISO |

| 1.6580 | 30CrNiMo8 | 4340 | 30H2N2M | 31CrNiMo8 |

1.6580 steel mechanical properties:

Tensile strength, Rm >800 N/mm2

Yield strength, Re: >590 N/mm2

Elongation, A: >12%

Impact strength, KV: >40 J