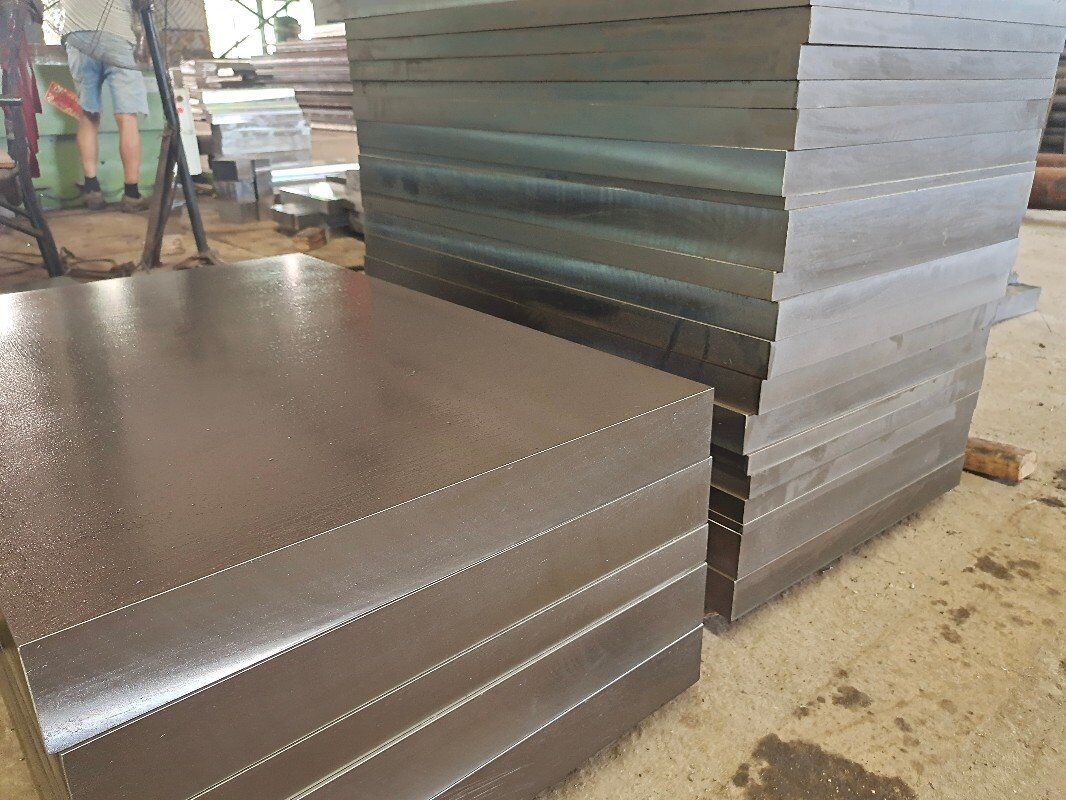

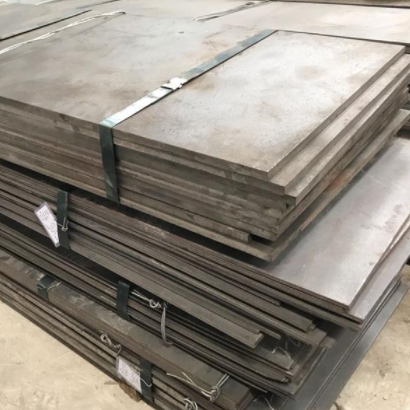

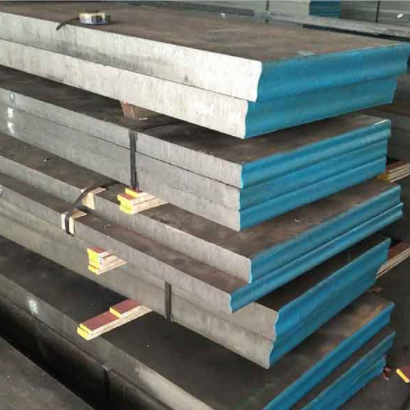

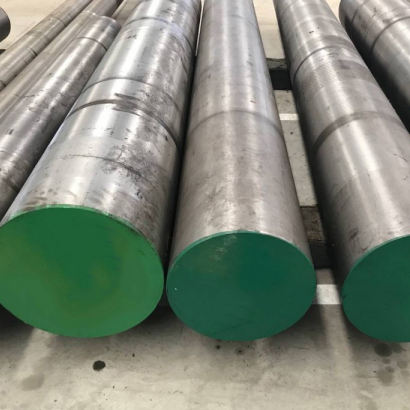

20CrNi2Mo low-carbon steel

20CrNi2Mo steel is a kind of high-quality low-carbon medium. Due to its low content of alloy elements and good coordination effect of various alloy elements, it is listed as the recommended standard in the world’s major industrial countries.

20CrNi2Mo equivalent grade:

| GB | SAE | JIS | GOST |

| 20CrNi2Mo | 4320 | SNCM420 | 20ХН2М |