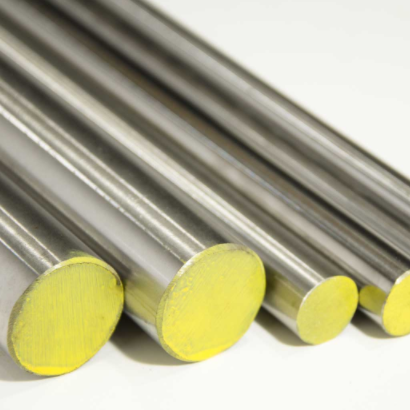

20CrMnMo case hardening steel

20CrMnMo steel is a high strength high grade carburizing steel(case hardening steel), alsp known as 20CrMnMo alloy steel. Its strength is higher than 15crmnmo, its plasticity and toughness are slightly lower, and its hardenability and mechanical properties are higher than 20CrMnTi steel.(20CrMnMo steel vs 20CrMnTi steel)

After quenching and tempering, it has good comprehensive mechanical properties and low-temperature impact toughness. After carburizing and quenching, it will get high bending strength and wear resistance, but it is easy to produce cracks during grinding. Poor weldability, suitable for resistance welding, it need to be preheated before welding and tempered after welding. Its machinability and thermal workability are good.

20CrMnMo Mechanical properties

Tensile strength (σ B / MPA): ≥ 1180

Yield strength (σ s / MPA): ≥ 885

Elongation after fracture (δ 5 /%): ≥ 10

Reduction of area (ψ /%): ≥ 45

Shock absorption energy (aku2 / J): ≥ 55

Brinell hardness (hbs100 / 3000) (annealed or tempered at high temperature): ≤ 217