4140 Steel Plate Near Me: OTAI’s Promise of Precision and Reliability

4140 Steel Plate Near Me: OTAI’s Promise of Precision and Reliability

In the complex interplay between engineering and manufacturing, the materials used are fundamental to the success of any project. Among these, 4140 alloy steel plate emerges as a critical element, not merely participating but orchestrating the performance and longevity of various applications. For those searching for “4140 steel plate near me,” the quest extends beyond just geographical proximity; it involves seeking out precision and superior quality.

OTAI: Your Trusted Partner in Steel Supply

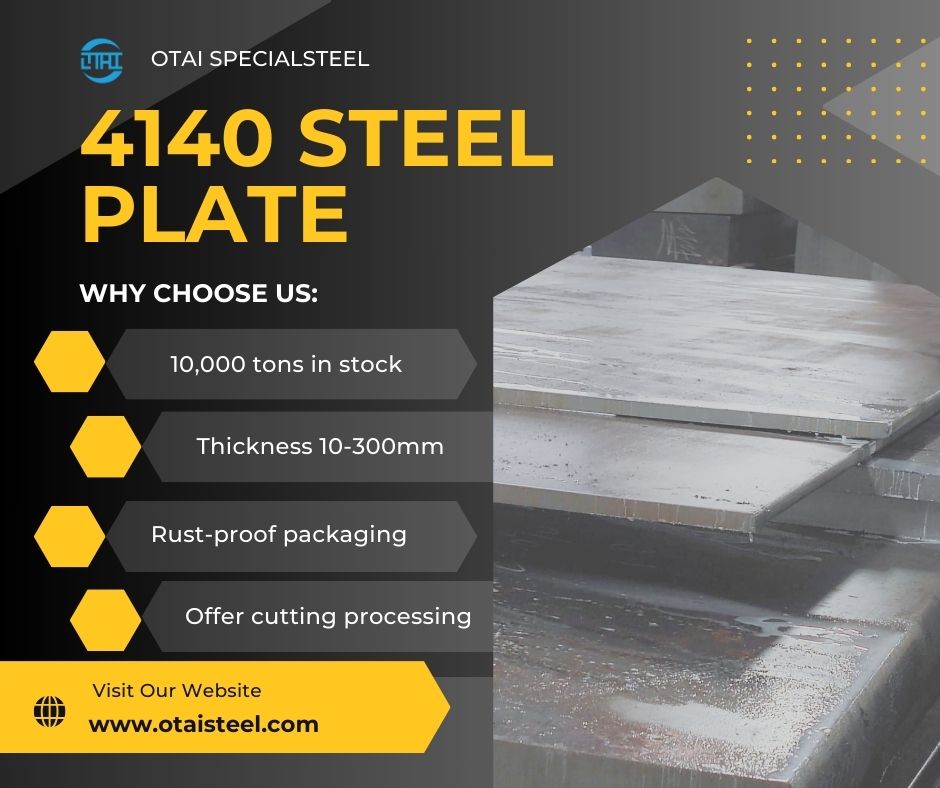

In the expansive landscape of steel suppliers, OTAI shines as a pillar of dependability. Here’s how we distinguish ourselves in the 4140 steel plate distribution market:

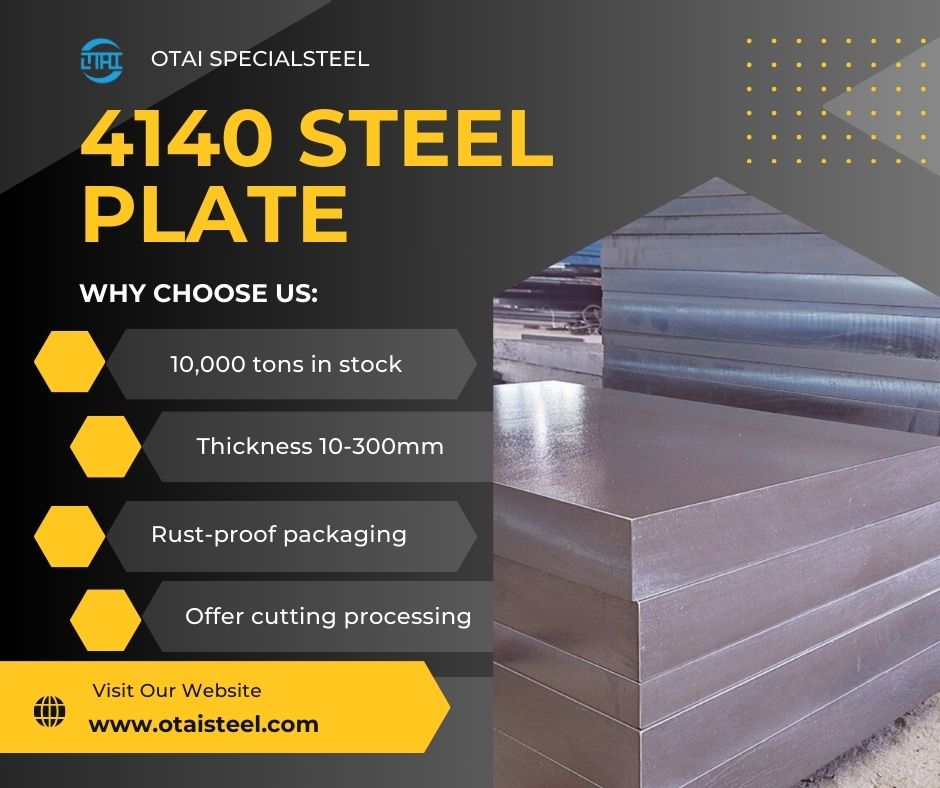

- Extensive Inventory:

Our inventory is not just substantial but immense, boasting 10,000 tons of 4140 steel plates. These plates are available in thicknesses ranging from 10mm to 300mm, ensuring we meet the specific requirements of your projects.

- Customized Cutting Services:

Precision is integral to our operations. We provide cutting services that transform bulk steel into exact components tailored to your specifications, ensuring a perfect fit for your design needs.

- Advanced Packaging Solutions:

We prioritize not only the delivery but also the protection of our products. Our innovative packaging solutions are crafted to ensure that your steel plates reach you in impeccable condition, maintaining their quality from our facility to your location.

Case Study: Setting Global Standards

Our reputation for excellence is supported by our successful collaborations with major industry players:

- Project Overview:

A leading multinational corporation launched a high-profile project reliant on the quality and timely delivery of 4140 steel plates.

- Challenges Addressed:

The project demanded adherence to rigorous specifications and a tight schedule.

- OTAI’s Success:

We not only met the technical and time requirements but also surpassed expectations by delivering ahead of schedule, underscoring our dedication to superior service and reliability.

The Unique Benefits of OTAI

- Stringent Quality Control:

Our 4140 steel plates undergo comprehensive testing, ensuring that ‘quality’ is a concrete standard rather than a mere promise.

- Commitment to Customer Satisfaction:

We view satisfied customers as our best advocates. Our unwavering focus on client satisfaction is reflected in our enduring relationships and high referral rates.

- Adaptable Delivery Options:

Understanding that each project has its own logistical challenges, we offer flexible delivery solutions tailored to meet diverse needs.

Conclusion: OTAI—Where Precision Meets Excellence

Opting for OTAI in your search for “4140 steel plate near me” means more than locating a supplier; it signifies partnering with a company dedicated to precision, quality, and customer focus.

Get in Touch

Are you ready to begin your project with the assurance of top-notch materials and exceptional service? Reach out to OTAI today and discover how our 4140 steel plates can elevate your project. Together, we can shape the future with every steel plate.

4140 Steel Plate Specifications: A Complete Breakdown

4140 Steel Plate Specifications: A Complete Breakdown 4140 HTSR Plate: The Backbone of Advanced Manufacturing

4140 HTSR Plate: The Backbone of Advanced Manufacturing The Unwavering Strength of 1/2 4140 Steel Plate

The Unwavering Strength of 1/2 4140 Steel Plate Exploring the Heat Treated Qualities of 4140 Steel

Exploring the Heat Treated Qualities of 4140 Steel 4140 Steel Heat Treated Properties: Unleashing the Full Potential of Alloy Steel

4140 Steel Heat Treated Properties: Unleashing the Full Potential of Alloy Steel A2 Steel Knives for Exceptional Precision and Durability

A2 Steel Knives for Exceptional Precision and Durability Why 4340 Steel Alloy from OTAI Steel is a Smart Choice

Why 4340 Steel Alloy from OTAI Steel is a Smart Choice 5140 Steel vs 4140 Steel: The Unraveling of Alloy Steel’s Dual Nature

5140 Steel vs 4140 Steel: The Unraveling of Alloy Steel’s Dual Nature Exploring the Properties of 4340 Steel in Engineering

Exploring the Properties of 4340 Steel in Engineering