30CrNiMo8 High-Grade Alloy Steel for Superior Industrial Results

30CrNiMo8 High-Grade Alloy Steel for Superior Industrial Results

Introduction:

In the realm of industrial materials, few can match the versatility and strength of 30CrNiMo8 alloy steel. This article delves into the unique properties of 30CrNiMo8, its applications, and how it sets the standard for performance in various industries.

Characteristics of 30CrNiMo8 Material:

- Chemical Composition: A detailed breakdown of the elements that make up 30CrNiMo8, emphasizing its alloying constituents that contribute to its superior qualities.

- Physical Properties: An overview of the material’s density, melting point, and thermal conductivity, setting the stage for understanding its practical applications.

Industrial Applications of 30CrNiMo8:

- Sector Insights: A look into the various sectors where 30CrNiMo8 excels, including aerospace, automotive, and heavy machinery.

- Performance Advantages: Highlighting the material’s resistance to wear, corrosion, and high temperatures, making it a top choice for demanding applications.

Mechanical Properties of 30CrNiMo8:

- Tensile Strength: Discussing the impressive strength-to-weight ratio that 30CrNiMo8 offers.

- Hardness and Toughness: An exploration of how the material balances hardness with the necessary toughness for resilience under stress.

Heat Treatment of 30CrNiMo8:

- Impact on Performance: The role of heat treatment in enhancing the mechanical properties of 30CrNiMo8.

- Common Methods: A description of the heat treatment processes commonly applied to 30CrNiMo8 to achieve desired outcomes.

Advantages of 30CrNiMo8 Machining:

- Cutting Services: An introduction to the precision cutting services available for 30CrNiMo8, ensuring optimal use of the material.

- Post-Processing: Details on the finishing touches that can be applied post-machining to ensure a high-quality surface finish.

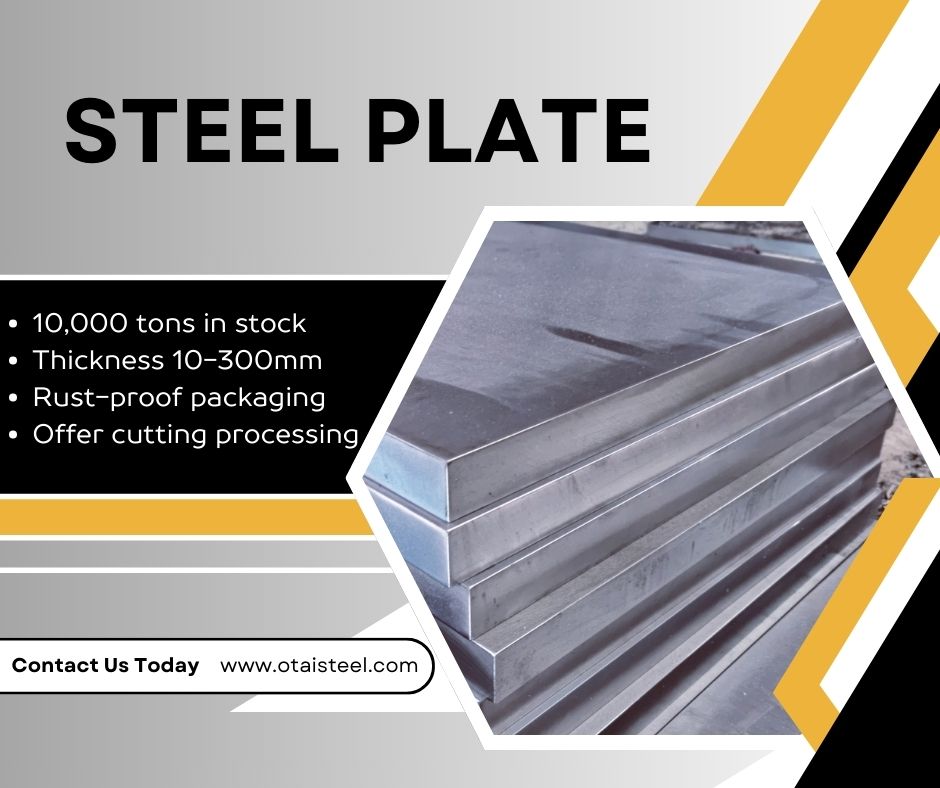

Packaging and Inventory Management of 30CrNiMo8:

- Importance of Packaging: The significance of proper packaging in preserving the integrity of 30CrNiMo8 during transit and storage.

- Stock Management: OTAI’s strategy for maintaining a substantial inventory of 30CrNiMo8, ready for quick dispatch to meet customer needs.

Case Study: 30CrNiMo8 alloy Material Supply to Global Enterprises:

- Supply Examples: Real-world examples of how OTAI has supplied 30CrNiMo8 to Fortune 500 companies, meeting stringent technical requirements.

- Customer Satisfaction: Testimonials and feedback from satisfied clients, showcasing the material’s reliability and OTAI’s commitment to quality.

Conclusion:

- A summary of the comprehensive benefits of 30CrNiMo8 material, emphasizing its role as a key player in the advancement of industrial applications.

- Acknowledging OTAI’s expertise in supplying 30CrNiMo8 High-Grade Alloy Steel and its dedication to customer satisfaction.

Call to Action:

- Encouraging potential clients to reach out to OTAI for more information on how 30CrNiMo8 can elevate their projects to the next level.

Understanding the Key Characteristics of 4340 Steel Products

Understanding the Key Characteristics of 4340 Steel Products Why 30CrNiMo8 Alloy Steel is Advantageous for Manufacturing

Why 30CrNiMo8 Alloy Steel is Advantageous for Manufacturing Key Uses of 4140 Pre Hardened Steel Plate

Key Uses of 4140 Pre Hardened Steel Plate Understanding 4340 Steel Applications

Understanding 4340 Steel Applications You Need to Know About 4140 Plate Steel Specifications

You Need to Know About 4140 Plate Steel Specifications What is the Mechanical Properties of 4140 Steel Plate

What is the Mechanical Properties of 4140 Steel Plate