4140 Steel Plate Solutions by OTAI: Improving Structural Resilience

4140 Steel Plate Solutions by OTAI: Improving Structural Resilience

Introduction

In the field of industrial materials, 4140 Alloy Steel Plate is very important for enhancing the structural integrity of various applications. From aerospace to automotive manufacturing, from oil and gas to heavy machinery industries, their demand for high-quality alloy steel has been growing. OTAI is a top supplier of 4140 Alloy Steel Plate, and our comprehensive services and solutions can meet these needs.

OTAI Overview

We has consistently led the alloy steel industry, delivering high-quality products to global customers. Renowned for its commitment to quality and customer satisfaction, OTAI has established itself as a trusted brand in the market.

Characteristics and Applications of 4140 Alloy Steel Plate

- Chemical Composition and Physical Properties

4140 alloy steel is distinguished by its unique chemical composition, prominently featuring chromium and molybdenum. These elements significantly enhance the mechanical properties of 4140, including strength, toughness, and hardness. These attributes make it exceptionally suitable for applications demanding superior durability and reliability.

- Applications in Various Industries

This alloy steel plate finds extensive use across diverse industries. In aerospace, it is pivotal for critical components due to its excellent strength-to-weight ratio. Automotive manufacturing relies on its ability to endure high stress and fatigue. In the oil and gas sector, it offers corrosion resistance and withstands high temperatures.

- Technical Requirements and Quality Control

The production and processing of 4140 alloy steel plates adhere strictly to rigorous technical standards to ensure high quality. OTAI maintains stringent quality control measures throughout the production process to guarantee each batch meets precise specifications.

Services and Advantages of OTAI

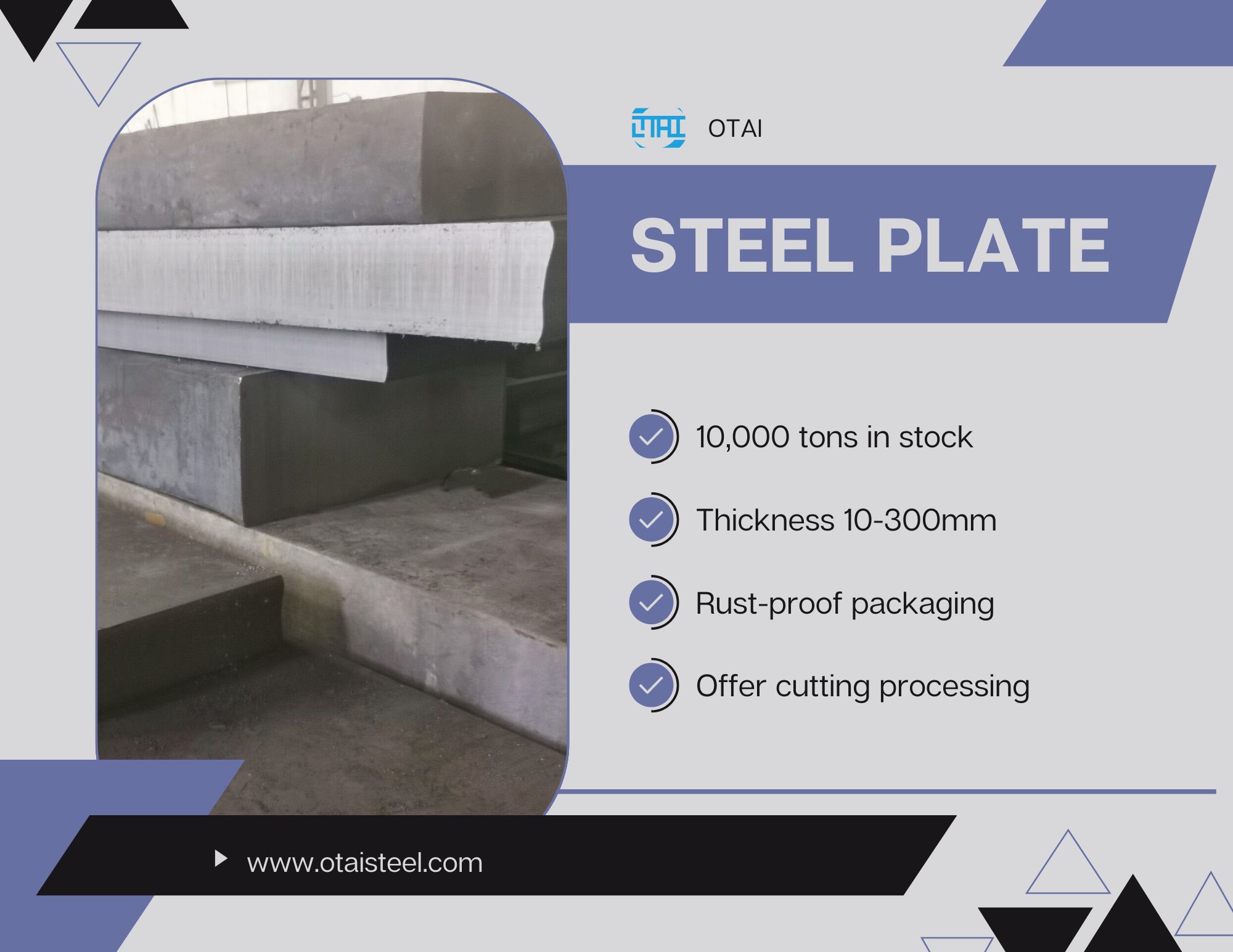

- Inventory Management and Availability

OTAI maintains a substantial inventory of 4140 alloy steel plates, ensuring prompt availability and timely delivery. This extensive stock enables OTAI to meet diverse client needs while offering flexibility and reliability in supply chain management.

- Cutting and Processing Services

In addition to supplying raw materials, OTAI provides tailored cutting and processing services. Whether precision cutting or custom shaping, OTAI’s advanced facilities and skilled technicians guarantee orders meet the highest standards of precision and quality.

- Packaging and Logistics

Ensuring the integrity of steel plates during transit is paramount. OTAI offers various packaging solutions, including banding, wooden crates, and rust prevention measures. Coupled with efficient logistics, OTAI ensures every shipment arrives in pristine condition.

- Customer Service and Support

Customer satisfaction drives OTAI’s operations. Their dedicated customer service team stands ready to address inquiries promptly and effectively, reinforcing OTAI’s reputation for responsiveness and reliability.

Case Studies and Customer Feedback

- Successful Applications

OTAI has contributed to numerous successful projects where 4140 alloy steel plates have played a pivotal role. From intricate engineering feats to everyday industrial applications, OTAI consistently delivers on its promise of performance and reliability.

- Recommendations from Satisfied Customers

Customers have praised OTAI for its quality and service. They are also very willing to recommend us to other customers.

Market Trends and Future Prospects of 4140 Alloy Steel Plate

- Market Demand Analysis

Driven by technological advancements and the need for strong materials, the demand for 4140 Alloy Steel Plate continues to rise. OTAI’s strategic inventory management and customer-centric approach enable it to meet this growing demand well.

4140 Steel Plate Solutions by OTAI: Improving Structural Resilience

OTAI distinguishes itself as a leading 4140 Alloy Steel Plate Suppliers through its commitment to quality, customer service, and innovation. Every facet of OTAI’s operations reflects its dedication to meeting and surpassing client expectations.

Call to Action

For those seeking a reliable supplier of 4140 alloy steel plates, OTAI stands ready. Contact us today to discover more about our products and services, and partner with OTAI for your next project.

Applications and Advantages of 30CrNiMo8 Alloy Steel in Manufacturing

Applications and Advantages of 30CrNiMo8 Alloy Steel in Manufacturing Exploring Heat-Treated 4340 Steel: Applications and Advantages

Exploring Heat-Treated 4340 Steel: Applications and Advantages 4140 Flat Plate Steel for Structural and Machining Applications

4140 Flat Plate Steel for Structural and Machining Applications 30CrNiMo8 Steel equivalent material: Everything You Need to Know

30CrNiMo8 Steel equivalent material: Everything You Need to Know The Journey of 4340 Steel: From Raw Material to Finished Product

The Journey of 4340 Steel: From Raw Material to Finished Product 4140 steel plate price-A Guide to Current Prices and Future Projections

4140 steel plate price-A Guide to Current Prices and Future Projections Introduction to 4340 Steel Heat Treatment

Introduction to 4340 Steel Heat Treatment