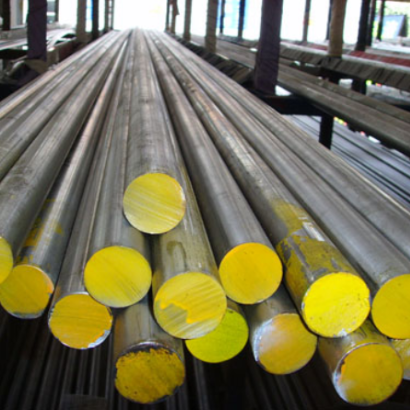

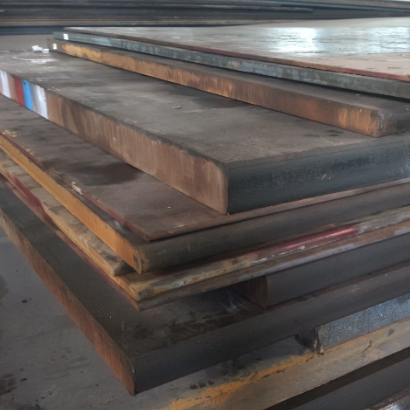

1.5217 alloy steel

1.5217 belongs to alloy steel, otai manufacture 1.5217 alloy steel. 1.5217 supplier.

1.5217 Steel equivalent standards:

| DIN | UNI | UK | AISI/SAE | GB |

| 1.5217 | 20MnVS6 | GR 55C | A 381 | 20MV |

1.5217 steel mechanical properties:

Yield strength [MPa]:410-450

Tensile strength[MPa]:550-750

Elongation A [%]:20

Reductionof area Z [%]:40

Hardness:< 220 HB

1.5217 alloy steel application

Tubular parts for the automotive, oil and gas, construction, general engineering and agricultural industry, such as bushes, hydraulic cylinders, hollow shafts, rings, hollow rolls for conveyors, nuts, gear wheels, shafts, axles, stuffing boxes, spindles, drill jigs, rolls etc.