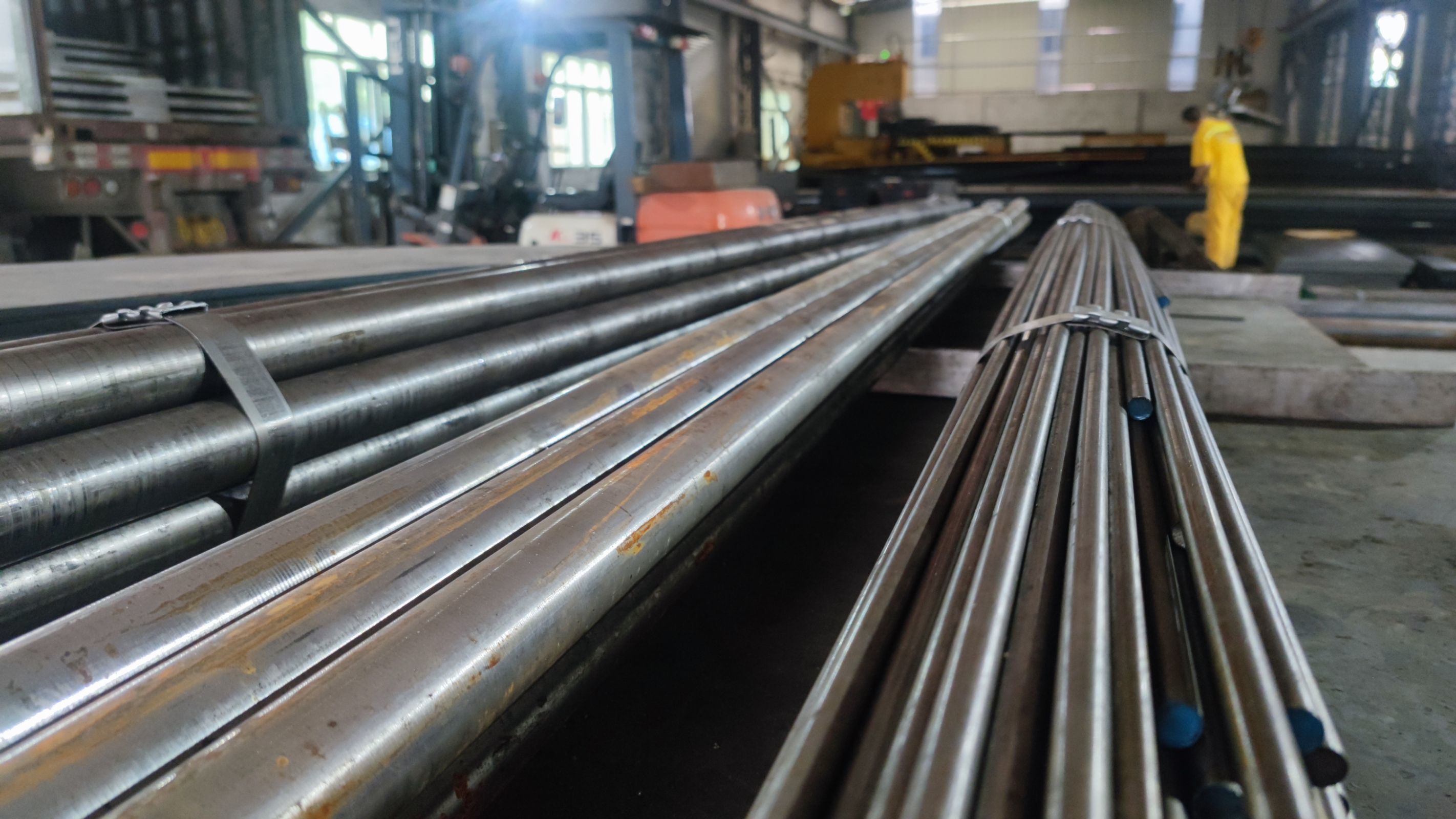

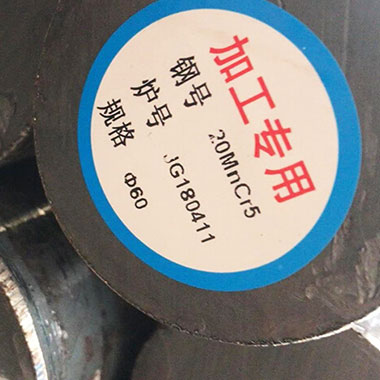

Nitriding Steel 32crmov12-10 Tool steel

Steel Grade: DIN 32CrMoV12-10 | W-Nr 1.7765 | 32CDV12

Steel Chemical Content

Nitriding steel grades contain strong nitride formers such as molybdenum, vanadium, aluminum or chromium.

Chemical composition

| C(%) | 0.30~0.35 | Si(%) | ≤0.35 | Mn(%) | ≤0.60 | P(%) | ≤0.025 |

| S(%) | 0.01 | Cr(%) | 2.80~3.20 | Mo (%) | 0.80~1.20 | V(%) | 0.25~0.35 |

Heat treatment

Nitriding is a heat-treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. The processes are thus similar to case-hardening but performed at a lower temperature.

The advantage with nitriding is mainly the reduced distortion behavior compared to carburizing and still give a high surface strength and ductile core.

However, since the process is performed at lower temperature, the same case depth as for carburizing will take considerable time to reach.

Nitriding can also increase the corrosion resistance of a component.

Application

Nitriding steel grades Typical applications are small gears, crankshafts and wear parts.