51CrMoV4 Structural steel

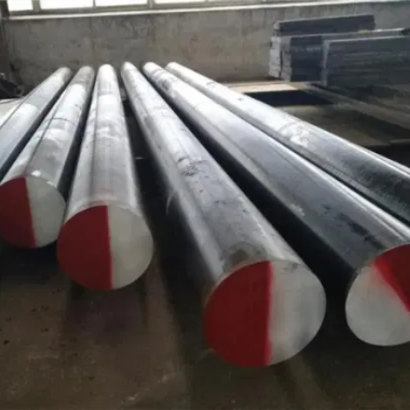

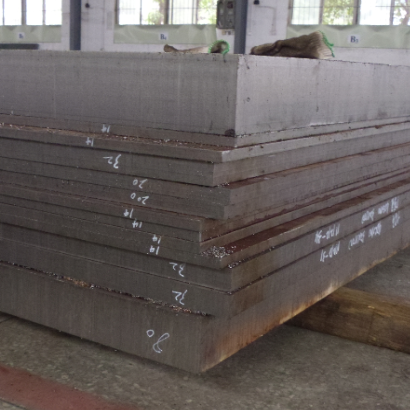

51CrMoV4 steel Otai stock huge stockist, belongs to Structural Cr-Mo-V-steel. 51CrMoV4 Steel plate.

Otai accepts all kinds of large, medium and small orders, and can help customers with cutting, machining, and heat treatment to solve customers’ problems in one stop.

Otai’s advantage:

1. There are thousands of tons of steel inventory in our warehouse, especially for 4140/42CrMo plate, Otai is the largest stockist in South China.

2. Small order can be received. Compared with large steel mills, MOQ is lower, which is more conducive to foreign small and medium stockers.

3. We can finish all kinds of machining process like milling, polishing, turning and other processing.

4. With independent testing equipment, including spectrometers, UT flaw detection equipment, etc., compared to traders, we can fully guarantee product quality for customers.

3 major traps in steel procurement:

Using low-value materials as high-value materials; Otai will never be provide shoddy goods.

Offering low prices to attract customers regardless of customer performance requirements; Otai will only quote the most accurate price based on customer needs.

Delivery is not possible within the delivery period, making customers unable to keep up with the project; Otai promises to deliver within the fastest delivery time.

Material 51CrMoV4 Equivalent:

| LH No. | Mat. No. | DIN | EN | AISI |

| 727 | 1.7701 | 51CrMoV4 | 51CrMoV4 | 4150 |

51CrMoV4 Properties(Mechanical properties):

Tensile Strength (Mpa):1158

Yield Strength (Mpa):1034

Elongation (%):15

Reduction in Area (%):53

Hardness (HB): 335