Precision manufacturing is the process of creating intricate components and products with high accuracy and tight tolerances. It’s an art that demands attention to detail, advanced technologies, and materials that can deliver uncompromising results.

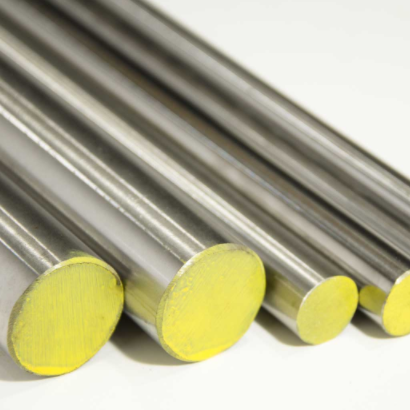

Unveiling A2 Steel’s Properties

The Composition that Matters

A2 steel, also known as air-hardening or cold work steel, boasts a composition that includes chromium, carbon, and manganese. These elements contribute to its exceptional hardness, wear resistance, and machinability.

A2 Steel’s Applications in Precision Manufacturing

Tool and Die Making

In precision manufacturing, the creation of molds, dies, and tools demands materials that can maintain their integrity over repeated use. A2 steel’s combination of toughness and wear resistance makes it an ideal choice for such applications.

Stamping and Forming

A2 steel’s hardness and machinability lend themselves to stamping and forming operations, where precision is crucial to achieving consistent results.

Fine Mechanical Components

From gears and bearings to intricate mechanical parts, A2 steel’s properties shine in applications where durability and precision are non-negotiable.

The Impact on Product Quality

Elevating Standards

A2 steel’s role in precision manufacturing extends beyond its physical properties. It contributes to the overall quality of products, ensuring they meet exact specifications and perform reliably.

A2 Steel and Innovation

Pushing Boundaries

As precision manufacturing continues to evolve, so does the demand for materials that can withstand increasingly stringent requirements. A2 steel rises to the occasion, enabling innovation in industries that demand excellence.

Challenges and Considerations

Overcoming Challenges

While A2 steel offers remarkable properties, it’s crucial to understand its limitations and how to optimize its use in various manufacturing processes.

In the realm of precision manufacturing, A2 steel stands as a testament to the synergy between materials science and engineering expertise. Its unique combination of properties makes it an invaluable asset, driving excellence in the creation of intricate components and products.