How to Heat Treat A2 Steel for Optimal Performance

Embarking on the journey of working with A2 steel opens the door to a world of possibilities. Understanding how to heat treat A2 steel is a critical aspect of maximizing its potential. In this guide, we’ll delve into the intricacies of the heat treatment process, ensuring you unlock the full capabilities of this versatile material.

Deciphering the Standard: A2 Steel’s Foundation

Standard Insights

Before delving into the heat treatment process, let’s revisit the foundation of A2 steel. Governed by the ASTM A681 standard, A2 steel adheres to industry benchmarks, ensuring a consistent quality that forms the basis for successful heat treatment.

Breaking Down Composition: The Core of A2 Steel

Chemical Composition Insights

Understanding the chemical composition of A2 steel is essential before embarking on heat treatment. With a blend of carbon, chromium, vanadium, and other elements, A2 steel achieves a balance that contributes to its high hardness, wear resistance, and the ability to retain an edge.

Applications Unleashed: A2 Steel’s Versatile Performance

Versatile Applications

Before we dive into heat treatment specifics, let’s appreciate the diverse applications of A2 steel. From crafting precision knives to manufacturing cutting tools, A2 steel’s versatility makes it a top choice for applications demanding durability and edge retention.

The Heat Treatment Process: A Step-by-Step Guide

Preparation: Setting the Stage

Begin the heat treatment journey by ensuring your A2 steel is clean and free from contaminants. Proper preparation sets the stage for a successful heat treatment process.

Initial Heating: Reaching Critical Temperatures

Gradually heat the A2 steel to its critical temperature, typically around 1,700°F (927°C). This allows for the transformation of the steel’s structure, setting the foundation for optimal hardness.

Quenching: The Rapid Cool Down

Quickly move the heated A2 steel into a quenching medium, often oil or air, to rapidly cool it down. This step is crucial for achieving the desired hardness and toughness.

Tempering: Fine-Tuning Hardness and Toughness

Tempering follows quenching and involves reheating the steel to a specific temperature, then allowing it to cool. This step balances hardness and toughness, preventing the steel from becoming too brittle.

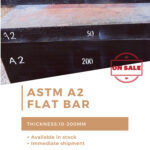

Size Matters: Tailoring A2 Steel to Your Needs

Sizing Options Explored

Consider the size of your A2 steel during heat treatment. Larger pieces may require adjustments in heating and quenching times to ensure uniform results.

Counting the Cost: Navigating A2 Steel Pricing

Pricing Considerations

Understanding the cost of A2 steel is vital for those considering heat treatment. While prices may vary based on factors like size, quantity, and supplier, investing in quality A2 steel ensures a material that responds well to the heat treatment process.

Sourcing Success: Finding the Right A2 Steel Supplier

Smart Sourcing Strategies

For those seeking A2 steel for heat treatment projects, finding a reliable supplier is key. Look for suppliers with a proven track record, certifications, and positive customer feedback to ensure quality materials.

Conclusion: Unleashing the Potential of A2 Steel through Heat Treatment

In conclusion, mastering the art of heat treating A2 steel is a journey that leads to unparalleled performance. By understanding the standard, composition, applications, and intricacies of the heat treatment process, you can unlock the full potential of A2 steel for your projects.