Seamlessly Joining Components with 30CrNiMo8 Alloy

In the world of metallurgy, the 30CrNiMo8 alloy stands out as a versatile powerhouse known for its exceptional strength and durability. One of its remarkable applications lies in the art of seamlessly joining components. In this exploration, we’ll delve into the unique properties of 30CrNiMo8 alloy, the processes involved in joining components, and the transformative impact it has across various industries.

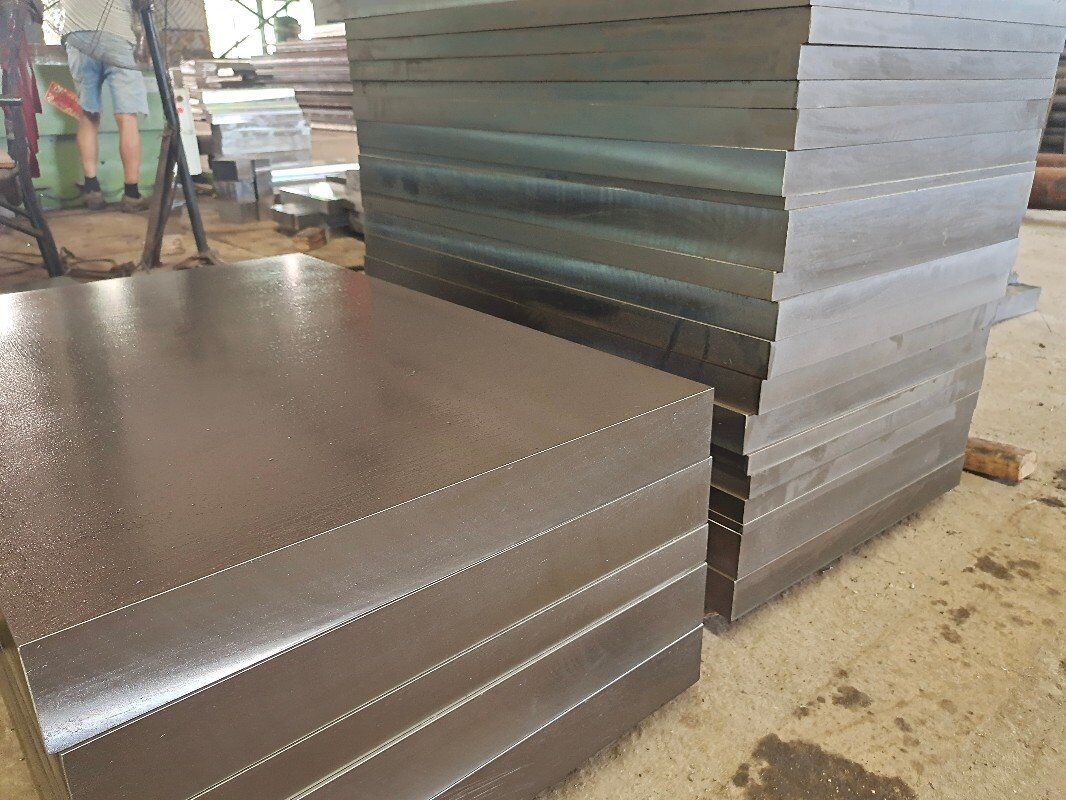

Unveiling the Powerhouse: Understanding 30CrNiMo8 Alloy

Before we embark on the journey of joining components, let’s acquaint ourselves with the star of the show—30CrNiMo8 alloy. Comprising chromium, nickel, and molybdenum, this alloy exhibits outstanding mechanical properties, making it a preferred choice for applications demanding robustness.

The Art of Joining: Why Seamlessness Matters

Seamless joining of components is a critical aspect in industries ranging from manufacturing to construction. It ensures the integrity of structures and machinery, minimizing weak points that could compromise performance. 30CrNiMo8 alloy, with its unique composition, brings a new level of strength to the process.

Welding Wonders: The Role of 30CrNiMo8 Alloy in Fusion

Welding, a fundamental method of joining metals, finds a perfect companion in 30CrNiMo8 alloy. The alloy’s excellent weldability allows for the creation of seamless joints, eliminating concerns about structural integrity. Whether in automotive frames or structural beams, the fusion achieved through welding with 30CrNiMo8 alloy enhances overall durability.

Bolstering Strength: The Impact of Heat Treatment

Heat treatment becomes a crucial player in the process of seamlessly joining components with 30CrNiMo8 alloy. Through controlled heating and cooling, the alloy’s properties are optimized, ensuring the joined components not only meet but exceed performance expectations. This additional step in the process contributes to the alloy’s renowned strength.

Navigating Challenges: Best Practices in Joining 30CrNiMo8 Alloy Components

While the process of joining components with 30CrNiMo8 alloy brings about substantial benefits, challenges may arise. Adhering to best practices, such as precise heat control during welding and careful consideration of component orientation, helps overcome these challenges. The result is a flawlessly integrated structure ready to withstand demanding conditions.

Beyond Welding: Alternative Methods of Joining

Welding is not the sole method for seamlessly joining components with 30CrNiMo8 alloy. Mechanical fastening, such as bolting or riveting, provides viable alternatives depending on the specific requirements of the project. Each method offers unique advantages, showcasing the adaptability of 30CrNiMo8 alloy to diverse joining techniques.

Quality Assurance: Meeting International Standards

Ensuring the seamless joining of components with 30CrNiMo8 alloy involves strict adherence to international standards. Certifications such as ASTM A29 and EN 10083-3 provide guidelines for the production and quality control of the alloy. This commitment to quality assurance guarantees that joined components meet or exceed industry standards.

Innovation in Engineering: Real-World Applications of Seamless Joining

The impact of seamlessly joining components with 30CrNiMo8 alloy reverberates across various industries. From the construction of high-rise buildings to the assembly of precision machinery, this alloy’s ability to create robust, seamless connections has led to innovations in engineering, ensuring structures and equipment withstand the test of time.