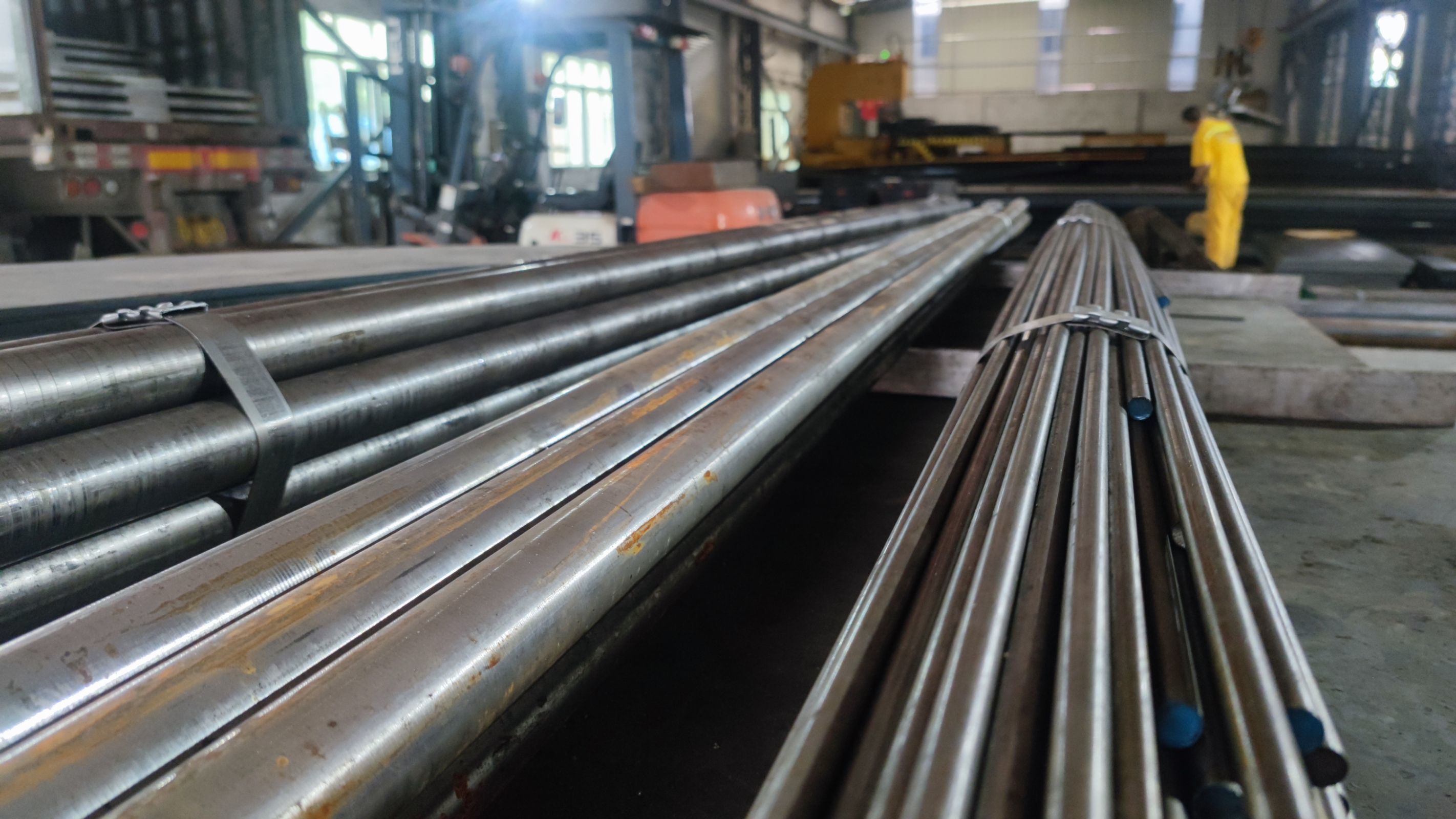

A2 steel, a versatile and widely used tool steel, is known for its exceptional characteristics that make it ideal for cutting tools. Its composition and structure imbue it with the attributes necessary for precision machining, from durability to sharpness retention.

Properties that Define A2 Steel’s Excellence

Hardness and Wear Resistance: The Key to Longevity

A2 steel’s exceptional hardness enables it to withstand the abrasion and wear that cutting tools encounter during operation. This property translates to longer tool life and reduced frequency of replacements.

Toughness: Balancing Strength with Durability

In the world of cutting tools, toughness is paramount. A2 steel strikes a balance between hardness and toughness, ensuring that tools can endure the mechanical stresses and impacts without shattering or losing their cutting edge.

A2 Steel in Cutting Tool Manufacturing

Creating Precision: Machining and Forming

A2 steel’s machinability allows manufacturers to craft intricate shapes and geometries with precision. Its uniform composition and fine grain structure ensure consistent performance across various cutting tool designs.

Tool Bits and Blades: Enhancing Efficiency and Performance

From drill bits to saw blades, A2 steel’s versatility shines through. Its ability to retain sharpness and withstand high cutting temperatures make it an invaluable asset in creating tools that deliver exceptional efficiency and accuracy.

Applications and Industries

Metalworking Marvel: A2 Steel in CNC Machining

In the realm of metalworking, CNC machining demands cutting tools that can withstand high-speed operations and maintain precision. A2 steel’s properties make it a top choice for producing tools that excel in this arena.

Woodworking Wonders: A2 Steel in Chisels and Planes

Woodworkers value A2 steel for its edge retention and resistance to chipping. Chisels and hand planes made from A2 steel maintain their sharpness, reducing the need for constant resharpening.

Paper, Plastic, and Beyond: Versatility in Non-Metal Cutting

A2 steel’s benefits extend beyond metalworking. It proves its worth in cutting tools designed for paper, plastic, and other materials, ensuring clean cuts and efficient operations.

Advantages of A2 Steel Cutting Tools

Extended Lifespan: Reduction in Downtime and Costs

The longevity of A2 steel cutting tools translates to fewer replacements, minimizing downtime and saving costs for manufacturers and industries reliant on precision cutting.

High-speed Performance: Meeting Demanding Production Needs

A2 steel’s ability to maintain its cutting edge at high speeds ensures efficient and timely production. This quality is particularly valuable in industries where productivity is paramount.

Maintaining and Caring for A2 Steel Tools

Proper Storage: Preventing Corrosion and Damage

To maximize the lifespan of A2 steel cutting tools, proper storage in controlled environments is crucial. This prevents corrosion and maintains the integrity of the tools.

Sharpening Techniques: Restoring Cutting Performance

Even the best cutting tools eventually dull over time. A2 steel’s sharpening characteristics allow for effective resharpening, restoring the tool’s original cutting performance.

Challenges and Innovations

Heat Treatment Optimization: Enhancing A2 Steel’s Properties

Ongoing research aims to optimize A2 steel’s heat treatment processes, fine-tuning its properties for specific cutting applications and improving overall performance.

Emerging Alloys: Pushing the Boundaries of Cutting Tool Performance

The cutting tool industry continually explores new alloy compositions to further enhance tool performance. A2 steel remains a foundation for innovation in this field.

In the world of cutting tools, A2 steel is a game-changer. Its unique combination of hardness, toughness, and machinability makes it an irreplaceable asset across industries that demand precision and efficiency. As technology advances and industries evolve, the impact of A2 steel on cutting tools continues to shape the future of manufacturing and precision engineering.