4140 steel is an alloy composed primarily of iron, with significant amounts of chromium and molybdenum. This unique blend imparts high tensile strength, good fatigue resistance, and excellent toughness. The presence of these elements enhances the material’s ability to withstand stress and perform well under demanding conditions, making it a sought-after choice in critical applications.

Demand and Supply Dynamics

The basic principles of economics play a significant role in determining the price of 4140 steel plates. When demand outpaces supply, prices tend to rise, and vice versa. Factors such as industrial growth, infrastructure projects, and global market conditions all influence the demand for 4140 steel plates, thereby impacting its price.

Manufacturing Process and Quality Standards

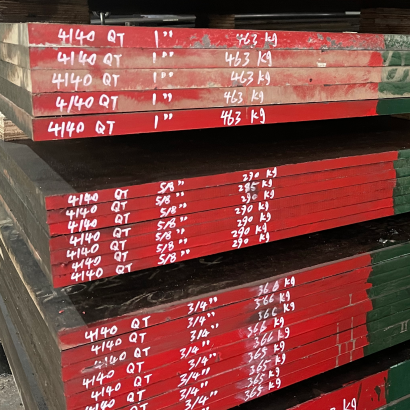

The process of producing 4140 steel plates involves precise metallurgical techniques, including quenching and tempering to achieve the desired hardness and mechanical properties. Manufacturers who adhere to strict quality standards often command a higher price for their products, as the assurance of consistent quality adds value to the end user.

Alloying Elements and Their Impact on Price

The prices of raw materials, such as chromium and molybdenum, can fluctuate due to global market conditions. Since these elements are integral to the composition of 4140 steel, their availability and cost directly influence the final price of the alloy.

Market Trends and Economic Factors

The cyclical nature of the steel industry and broader economic trends can impact the pricing of 4140 steel plates. During periods of economic growth, demand for steel increases, driving prices higher. Conversely, economic downturns can lead to decreased demand and subsequently lower prices.

Plate Dimensions and Thickness

The size and thickness of the 4140 steel plate significantly affect its cost. Larger plates and thicker dimensions require more raw material and energy during manufacturing, contributing to a higher price point.

Heat Treatment and Machinability

The heat treatment process used to enhance the mechanical properties of 4140 steel can influence its price. Plates that have undergone specialized heat treatments for improved hardness and toughness may come at a premium due to the additional processing steps involved.

Brand Reputation and Certification

Renowned manufacturers with a history of producing high-quality steel products often command higher prices for their 4140 steel plates. Certifications and third-party testing that validate the alloy’s performance can also contribute to higher costs.

Geographic Location and Shipping Costs

The geographical location of the manufacturer and the buyer can impact the price due to transportation and shipping expenses. Proximity to raw material sources and end markets can mitigate or exacerbate these costs.

Comparing 4140 Steel with Other Alloys

Analyzing the cost of 4140 steel plates in comparison to other alloys helps potential buyers assess their options based on budget and performance requirements. It’s important to consider the long-term benefits and value that 4140 steel brings to the table.

Customization and Special Requirements

Clients with specific customization or unique requirements might need additional processes or modifications during production. These customized processes can impact the final price of the 4140 steel plates.

Secondary Processes and Surface Finish

Surface finish treatments, such as coatings and polishing, can add value to 4140 steel plates, affecting their cost. These processes enhance corrosion resistance and aesthetics, making the alloy more appealing to customers.

Sustainability and Eco-Friendly Practices

In an environmentally conscious world, manufacturers that adopt sustainable practices might invest in technologies that minimize waste and energy consumption. While these efforts contribute to a greener planet, they can also influence the price of 4140 steel plates.

The price of 4140 steel plates is the result of a complex interplay of factors. From alloy composition and market trends to manufacturing processes and customization, a multitude of elements contribute to the final cost. Understanding these intricacies empowers buyers to make informed decisions based on their budget, application requirements, and long-term objectives.