In the world of metallurgy, certain materials stand out for their exceptional qualities and versatile applications. A2 steel is one such material that has captivated engineers, manufacturers, and enthusiasts alike. With its remarkable combination of strength, durability, and precision, A2 steel has become a cornerstone in various industries. This article takes you on a journey to explore the wonders of A2 steel, from its composition to its remarkable uses.

Understanding A2 Steel: Composition and Characteristics

The Alloy Blueprint

A2 steel, also known as “air-hardening” or “cold work” steel, is composed of iron, carbon, chromium, molybdenum, and vanadium. This unique blend gives A2 steel its distinctive properties, including its ability to maintain hardness even at room temperature.

The Power of Hardness

One of the standout features of A2 steel is its exceptional hardness. This property is crucial in applications that require resistance to wear, abrasion, and deformation. The combination of elements in A2 steel creates a material that can withstand the rigors of demanding tasks.

Versatile Applications Across Industries

Tool Making Precision

A2 steel is a preferred choice in the realm of tool making. Its high hardness and excellent edge retention make it ideal for crafting cutting tools, dies, and molds. From industrial manufacturing to woodworking, A2 steel ensures precision and longevity.

Manufacturing Excellence

Industries like automotive and aerospace rely on A2 steel for producing components that demand both accuracy and durability. Whether it’s intricate parts or complex machinery, A2 steel’s properties contribute to the overall performance of these industries.

Cold Work Magic

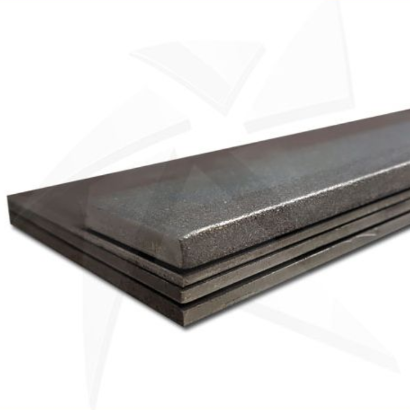

A2 steel’s name, “cold work,” signifies its prowess in applications that involve deformation at lower temperatures. It excels in tasks such as stamping, bending, and forming, where its toughness and wear resistance shine.

The Craft of A2 Steel: Manufacturing Process

Forging the Future

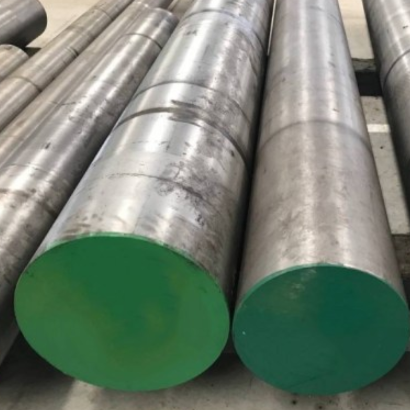

The journey of A2 steel begins with forging. Heating the steel to specific temperatures and shaping it under controlled pressure aligns its grain structure, enhancing its strength and mechanical properties.

The Heat Treatment Dance

Heat treatment is a pivotal step in optimizing A2 steel’s performance. Through processes like quenching and tempering, the steel’s hardness, toughness, and overall resilience are fine-tuned to meet specific application requirements.

Mastering A2 Steel: Tips and Techniques

Precision in Tooling

For tool makers, choosing the right heat treatment process is key to unlocking A2 steel’s potential. Proper hardening and tempering can result in tools that maintain their sharp edges, ensuring consistent performance.

Tailoring for Toughness

Balancing hardness and toughness is an art when working with A2 steel. Adjusting the tempering temperature allows engineers to fine-tune the steel’s properties, adapting it to the specific stresses it will encounter.

A2 steel, with its exceptional blend of strength, hardness, and versatility, has proven itself as a foundational material in numerous industries. From crafting precision tools to shaping the future of manufacturing, A2 steel’s wonders continue to unfold. Its composition, processing techniques, and applications all come together to reveal a material that embodies both strength and precision.