Investigating the Wear Resistance of 4140 Alloy Steel Plates

Investigating the Wear Resistance of 4140 Alloy Steel Plates

In response to the demand for materials capable of enduring rigorous industrial applications, specialized steel grades like 4140 alloy steel have emerged as pivotal choices. This article focuses on the critical aspect of hardness in 4140 alloy steel, which profoundly influences its performance across various applications.

Understanding 4140 Alloy Steel Plates

4140 alloy steel is a high-strength, low-alloy (HSLA) steel enriched with chromium and molybdenum, enhancing its hardness, tensile strength, and yield point. Its composition and heat treatment impart exceptional work-hardening properties, making it ideal for applications requiring robust mechanical resistance.

The Science Behind Hardness

Hardness, the measure of a material’s resistance to deformation through indentation, is quantified in 4140 alloy steel using Rockwell, Brinell, or Vickers hardness tests. These tests provide precise insights into the material’s mechanical properties.

The Role of Heat Treatment in Hardness

Maximizing the potential of 4140 alloy steel hinges on meticulous heat treatment processes. Controlled heating and cooling alter the steel’s microstructure, directly impacting its hardness:

- Austenitizing: Heating initiates the formation of austenite.

- Quenching: Rapid cooling transforms austenite into martensite, a hard yet brittle phase.

- Tempering: Subsequent heating and controlled cooling enhance toughness while preserving hardness.

Achieving Optimal Hardness Through Processing

At OTAI, mastery of these heat treatment methods ensures that 4140 alloy steel plates achieve precise hardness levels tailored to specific requirements. This underscores our commitment to delivering quality and meeting client expectations.

Mechanical Properties and Their Significance

Hardness significantly influences key mechanical properties of 4140 alloy steel:

- Tensile Strength: Resistance to pulling forces before fracture.

- Yield Strength: Point at which plastic deformation begins.

- Elongation: Measure of ductility and deformation capacity before failure.

Applications of 4140 Alloy Steel

4140 alloy steel finds extensive use in industries requiring high strength, hardness, and wear resistance, including:

- Automotive: Gears, axles, and drive shafts.

- Aerospace: Landing gear and structural components.

- Manufacturing: Machinery parts demanding durability and wear resilience.

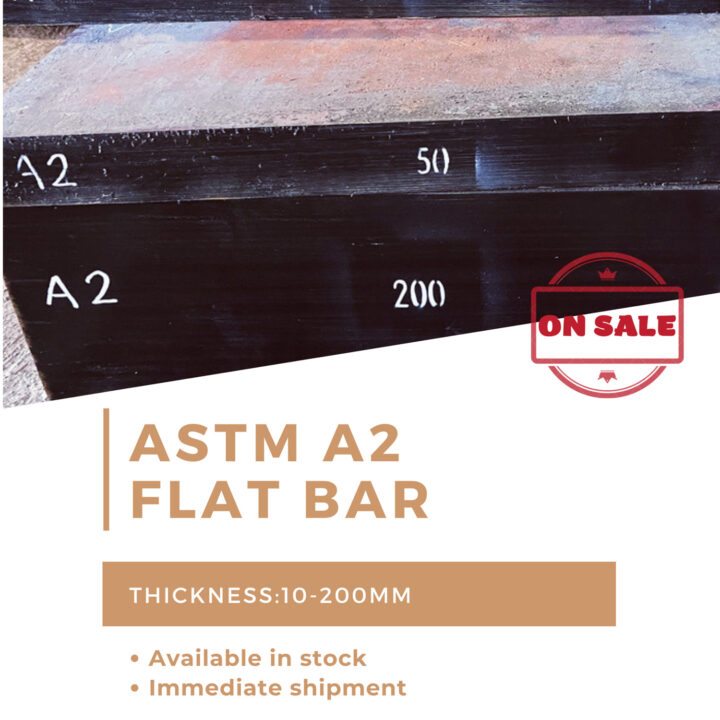

Stock Availability and Customization Services

OTAI maintains a comprehensive inventory of 4140 alloy steel plates in various thicknesses, ensuring prompt availability and rapid response to client orders. Our customization services include precision cutting, drilling, tapping, and tailored dimensions to meet precise project specifications.

Quality Assurance and Packaging

Stringent quality controls uphold international standards for hardness and mechanical properties. Our packaging solutions incorporate corrosion prevention measures and robust materials to safeguard steel integrity during transportation.

Meeting Global Technical Standards

Partnering with industry leaders affirms our capability to meet stringent technical requirements. Each batch of steel is accompanied by detailed documentation, including hardness certificates and mechanical property reports.

Investigating the Wear Resistance of 4140 Alloy Steel Plates

The diverse hardness characteristics of 4140 alloy steel plates dictate their performance in demanding environments. OTAI’s expertise in heat treatment ensures our plates achieve the optimal balance of hardness, strength, and toughness required for a wide range of applications. For tailored solutions that meet your exacting hardness specifications, trust OTAI as your partner in precision-engineered steel products. Contact us today to explore how we can support your project with quality and precision.