Engineering Steel 30crnimo8

What is Engineering Steel?-30crnimo8 steel Alloy Stee

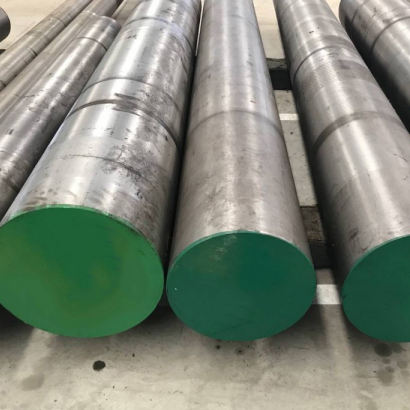

30crnimo8 round bar

IN STOCK

READY FOR SHIPMENT

1.)Engineering Steel Alloying elements

Engineering Steel is a steel that has had small amounts of one or more alloying elements (other than carbon) such as manganese, silicon, nickel, titanium, copper, chromium, and aluminium added.

2. Relevant Specification for 30CrNiMo8 Material

| EN 10083-3 | BS970 |

| 30CrNiMo8 / 1.6580 | 823M30 |

3. DIN 30CrNiMo8 Chemical Composition

| GRADE | CHEMICAL COMPOSITION | |||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | |

| max | max | max | ||||||

| 30CrNiMo8 / 1.6580 | 0,26 ~ 0,34 | 0,40 | 0,50 ~ 0,80 | 0,025 | 0,035 | 1,80 ~ 2,20 | 0,30 ~ 0,50 | 1,80 ~ 2,20 |

2.) Engineering Steel Properties

This produces specific properties that are not found in regular carbon steel.

Engineering Steels are workhorses of industry because of their economical cost, wide availability, ease of processing, and good mechanical properties. Alloy steels are generally more responsive to heat and mechanical treatments than carbon steels.

Engineering steels are essentially wrought steels designed for mechanical and engineering applications.

These require critical and often stringent levels of elasticity, strength, ductility, toughness, and fatigue resistance. In some cases, it may also require resistance to high or low temperatures, corrosive and other aggressive environments.

3) Engineering Steel Application:

Applications of advanced high-strength steels, sometimes called ultra-high strength steels, are finding their way into current production vehicles all over the world because of their unique qualities that allow for lighter weight parts that are as strong or stronger than conventional steel counterparts.

There is a great variety of engineering steel types and shapes. Each is carefully tailored to meet specific user requirements, in terms of properties and performance and in some cases to facilitate the manufacturing and fabrication techniques.

These techniques are then used to make components or parts. The composition, process route and heat treatment parameters are carefully selected to meet the customers’ needs.

4) Engineering Steel 30crnimo8 Applications:

1.Grade 30CrNiMo8 is used for production of heavily loaded parts, shafts and drive axes, steering shafts, crankshafts of engines, screws and elements exposed to temperatures in the power industry.

2. 30CrNiMo8 equal to 1.6580, 30NCD8, 30CND8 alloy steel

3. Alloyed structural steel with medium hardenability designed for heavy duty components, characterized by high elasticity and strength properties reaching over 1560 N/mm2 at small diameters. When softened, the hardness reaches max. 248 HRB.