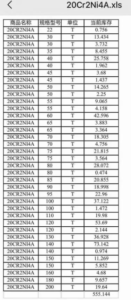

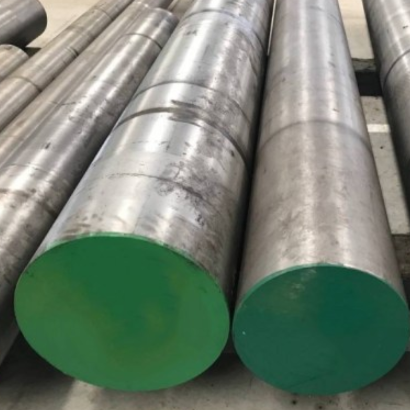

20Cr2Ni4 Alloy Steel Plate

1)20Cr2Ni4 steel is a high-quality Cold work tool steel, It belongs to the high-quality high carbon alloy tool steel. Oil Quenched & Tempered Hardness is 423 HB.

2) 20Cr2Ni4 Chemical composition

| C(%) | 0.17~0.23 | Si(%) | 0.17~0.37 | Mn(%) | 0.30~0.60 | Cr(%) | 1.25~1.65 |

| Ni(%) | 3.25~3.65 |

3) 20Cr2Ni4 Mechanical Properties

The mechanical properties of 20Cr2Ni4 tool steels are outlined in the following table.

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV/Ku (J) |

Elongation A (%) |

Reduction in cross-section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HB) |

|---|---|---|---|---|---|---|

| 155 (≥) | 945 (≥) | 14 | 32 | 31 | Solution and Aging, Annealing, Ausaging, Q+T, etc | 423 |